Steel grating and swage-locked grating are two popular types of gratings used in various industrial and commercial applications. Both types of gratings have their unique features and advantages, making it essential to understand the differences between them to make an informed decision for your specific needs.

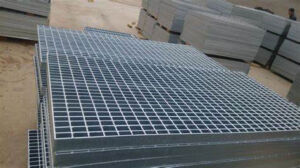

Steel grating is constructed from a series of parallel, flat bars that are welded together at perpendicular crossbars. This design provides high strength and stiffness, making it suitable for heavy-duty applications such as industrial flooring, catwalks, and trench covers. The open design allows for easy drainage and airflow, making it ideal for outdoor use.

On the other hand, swage-locked grating is manufactured by permanently locking crossbars and bearing bars at the intersection using tremendous hydraulic pressure. This process creates a rigid, one-piece panel with a smooth surface, making it ideal for architectural and aesthetic applications such as sunshades, fencing, and building facades. The flush top surface also provides a comfortable walking surface, making it suitable for pedestrian areas.

When comparing the two types of gratings, one of the key differences is the manufacturing process. Steel grating is typically produced through welding, which can result in a slightly rough surface and some degree of deformation. In contrast, swage-locked grating is manufactured without welding, resulting in a smooth and flat surface with no weld spatter or burn marks, providing a more polished and professional appearance.

In terms of load capacity, steel grating is known for its high strength and durability, making it suitable for heavy traffic and industrial applications. The sturdy construction allows it to withstand heavy loads and impact, making it a popular choice for areas with forklift and vehicular traffic. Swage-locked grating, while still strong and rigid, is more commonly used in architectural and decorative applications where heavy loads are not a primary concern.

Another important consideration is the installation and maintenance of the two types of gratings. Steel grating is relatively easy to install and can be customized to fit specific requirements. However, it may require regular maintenance such as painting or galvanizing to prevent corrosion and ensure longevity. Swage-locked grating, on the other hand, is often supplied in pre-assembled panels, making installation quick and straightforward. The smooth surface also requires minimal maintenance, making it a cost-effective choice in the long run.

In terms of cost, steel grating is generally more affordable than swage-locked grating, making it a popular choice for budget-conscious projects. The simple manufacturing process and widespread availability of steel materials contribute to its cost-effectiveness. Swage-locked grating, while offering a more polished and aesthetically pleasing finish, tends to be more expensive due to the precision manufacturing process and higher quality finish.

In conclusion, both steel grating and swage-locked grating have their unique characteristics and advantages, making them suitable for different applications. Steel grating is ideal for heavy-duty industrial use, offering high strength and durability at a more affordable cost. Swage-locked grating, on the other hand, is more commonly used in architectural and decorative applications, providing a polished finish and minimal maintenance requirements. Understanding the differences between the two types of gratings is crucial in selecting the most suitable option for your specific project needs.