Steel grating and aluminum grating are two popular materials used in various applications. When comparing steel grating vs. aluminum grating, it’s important to consider factors such as strength, durability, corrosion resistance, and cost.

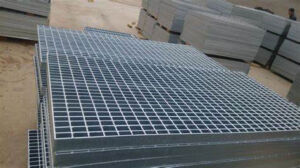

Steel grating is known for its high strength and load-bearing capacity, making it ideal for heavy-duty applications such as industrial flooring, catwalks, and trench covers. On the other hand, aluminum grating is lightweight and corrosion-resistant, making it suitable for applications where weight is a concern, such as pedestrian walkways and platforms.

One of the key differences between steel grating and aluminum grating is their material composition. Steel grating is made from carbon steel, which provides excellent strength and durability. In contrast, aluminum grating is made from aluminum alloy, offering a lightweight and corrosion-resistant solution.

In terms of corrosion resistance, aluminum grating outperforms steel grating due to its natural oxide layer, which provides protection against rust and corrosion. This makes aluminum grating a preferred choice for outdoor and marine applications where exposure to moisture and harsh environments is a concern.

When it comes to cost, steel grating is generally more affordable than aluminum grating. However, the long-term cost of ownership should also be taken into account, as aluminum grating’s corrosion resistance may result in lower maintenance and replacement costs over time.

Another factor to consider when comparing steel grating vs. aluminum grating is the installation process. Steel grating is typically heavier and requires more labor-intensive installation, while aluminum grating’s lightweight nature makes it easier to handle and install, reducing labor costs and installation time.

In terms of aesthetics, both steel grating and aluminum grating offer various design options to suit different architectural and industrial requirements. Steel grating is available in a range of surface profiles and can be customized for specific applications, while aluminum grating is known for its sleek, modern appearance.

When it comes to sustainability, aluminum grating is a more environmentally friendly option compared to steel grating. Aluminum is fully recyclable and requires less energy to produce, making it a sustainable choice for green building projects and eco-friendly initiatives.

In summary, the choice between steel grating and aluminum grating depends on the specific requirements of the application. While steel grating offers superior strength and affordability, aluminum grating excels in corrosion resistance, lightweight design, and sustainability. By carefully evaluating the factors of strength, durability, corrosion resistance, cost, installation, aesthetics, and sustainability, the most suitable grating material can be selected for each unique project.