Galvanized steel gratings, an important product of XINXING GRATING, are widely utilized in industrial and commercial settings because of their remarkable durability and strength. One question that frequently arises regarding these gratings, especially when considering the title “Are Galvanized Steel Gratings Rust Proof?”, is about their resistance to rust.

XINXING GRATING, with its long – standing history since 1971 and its status as a core enterprise under Xinxing International Group supervised by SASAC, has extensive knowledge of galvanized steel gratings. The process of galvanization plays a crucial role in determining the rust – proof nature of these gratings. Galvanization involves applying a protective zinc coating to the steel, which can be achieved through methods like hot – dip galvanizing or electroplating. Our company, having introduced Japan’s fully automatic steel grating production line in 1994 and developed further with 3 暑い – dip galvanizing production lines among other advanced facilities, has a deep understanding of this process.

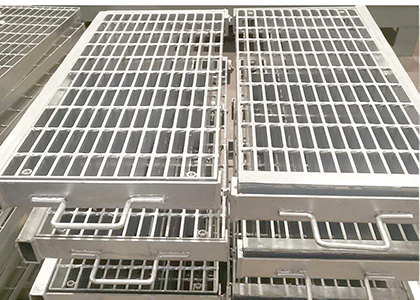

The zinc coating on the galvanized steel gratings acts as a sacrificial anode. This means that in the presence of corrosive elements, the zinc corrodes preferentially before the steel itself. This unique property makes galvanized steel gratings highly resistant to rust and corrosion. As a result, these gratings are highly suitable for outdoor applications and harsh environments. At XINXING GRATING, we produce a wide range of steel grating products with different specifications. Our ability to produce flat steel from 19*3mm to 150*10mm and grating with spacing from 12.5mm to 100mm ensures that the galvanized steel gratings we manufacture can meet various project requirements while maintaining their rust – resistant properties.

In addition to the zinc coating, the design of the galvanized steel gratings also contributes to their rust resistance. The open grid pattern of the steel gratings is an important feature. This pattern allows for efficient drainage of water and other liquids. At XINXING GRATING, our advanced production capabilities enable us to create steel gratings with optimal grid designs. By preventing the accumulation of moisture, the risk of rust formation is significantly reduced. Moreover, the high strength of the steel used in our gratings, which is a result of our quality production process including 4 flat steel production lines and 17 高度な圧力溶接生産ライン, makes the gratings less likely to be damaged. This helps in maintaining the integrity of the galvanized coating and thus enhances the rust – proof performance.

However, it must be noted that while galvanized steel gratings are highly rust resistant, they are not entirely immune to corrosion. Over time, especially in high – traffic areas or when exposed to certain chemicals, the zinc coating may gradually wear down. XINXING GRATING, as a company committed to providing high – quality products and excellent customer service, always emphasizes the importance of regular inspection and maintenance. With our nationally recognized enterprise technology R&D center and a post – 博士号モバイルワークステーション, we are constantly researching ways to improve the durability of our products. By following proper maintenance procedures, the lifespan of the galvanized steel gratings can be prolonged, and their optimal performance in demanding environments can be ensured.

おわりに, answering the question “Are Galvanized Steel Gratings Rust Proof?”, we can say that they are indeed rust proof to a large extent. This is due to the effective combination of the protective zinc coating and the well – designed structure of the steel gratings. XINXING GRATING’s expertise in manufacturing and its commitment to quality ensure that our galvanized steel gratings provide reliable performance in various applications. Regular maintenance and inspection are essential to maintain their rust – proof characteristics and to make the most of these excellent steel grating products in industrial and commercial projects.