Composite steel grating for waste treatment plants has emerged as a vital component in modern wastewater management systems. This innovative material combines strength, স্থায়িত্ব, and corrosion resistance, making it ideal for harsh environments. With the increasing focus on sustainability and efficiency in waste treatment, যৌগিক ইস্পাত ঝাঁঝরি offers a compelling solution for plant operators.

One of the primary advantages of composite steel grating for waste treatment plants is its lightweight nature. Unlike traditional steel grating, which can be cumbersome and difficult to handle, composite options are significantly lighter, allowing for easier installation and maintenance. This is particularly beneficial in facilities where access is limited or where heavy equipment cannot be used.

In addition to being lightweight, composite steel grating boasts exceptional resistance to corrosion. Waste treatment plants often deal with aggressive chemicals and moisture, which can quickly degrade standard materials. The corrosion-resistant properties of composite steel grating ensure a longer lifespan, reducing the need for frequent replacements and maintenance, ultimately saving costs for plant operators.

The installation process of composite steel grating is streamlined, which further enhances its appeal for waste treatment facilities. The grating can be easily cut and customized on-site, allowing for quick adjustments to fit specific applications. This flexibility is crucial in environments where space is at a premium and custom solutions are often required.

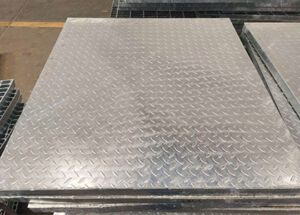

Safety is a paramount concern in waste treatment plants, and composite steel grating contributes significantly to creating a safer working environment. The slip-resistant surface of the grating minimizes the risk of accidents, particularly in wet or slippery conditions. By enhancing safety, composite steel grating helps protect workers and reduces liability for plant operators.

Another essential feature of composite steel grating for waste treatment plants is its load-bearing capabilities. These gratings are designed to withstand heavy loads, making them suitable for areas with high foot traffic or where heavy equipment may be used. This strength ensures that the grating will not warp or bend under pressure, maintaining its integrity over time.

Environmental sustainability is a critical factor in the design and operation of waste treatment plants. Composite steel grating is often manufactured using recycled materials, contributing to a circular economy. By choosing composite options, plant operators can reduce their environmental footprint while still achieving high performance and durability.

The aesthetic appeal of composite steel grating is another consideration for waste treatment plants. While functionality is the primary concern, the visual aspect cannot be overlooked. Composite materials can be designed in various colors and finishes, allowing for a more visually appealing installation that can blend seamlessly with the surrounding environment.

In terms of cost-effectiveness, composite steel grating presents a compelling case for waste treatment facilities. While the initial investment may be higher than traditional materials, the long-term savings associated with reduced maintenance, replacement costs, and improved efficiency make it a wise choice. This economic advantage is particularly important for municipalities and organizations operating on tight budgets.

Maintenance of composite steel grating is minimal compared to other materials. The non-porous surface resists staining and accumulation of debris, making cleaning easier and less frequent. This characteristic is especially beneficial in waste treatment plants, where cleanliness is essential to prevent contamination and ensure operational efficiency.

The versatility of composite steel grating allows it to be used in various applications within waste treatment plants. From walkways and platforms to covers for drainage channels, the adaptability of this material means it can meet diverse needs. This multifunctionality reduces the need for multiple types of grating, simplifying inventory and procurement processes.

One of the emerging trends in the use of composite steel grating is its integration with smart technologies. Some manufacturers are developing gratings equipped with sensors that monitor load, wear, পরিবেশগত অবস্থা. This innovation can provide real-time data to plant operators, enhancing decision-making and maintenance scheduling.

The installation of composite steel grating can also contribute to energy efficiency in waste treatment plants. By allowing for better airflow and drainage, these gratings can help optimize the operation of various systems, reducing energy consumption. This aspect aligns with the broader goals of sustainability and efficiency in waste management.

When selecting composite steel grating for waste treatment plants, it is essential to consider the specific requirements of the facility. Factors such as load capacity, chemical exposure, and environmental conditions should guide the selection process. Consulting with manufacturers or industry experts can help ensure the right choice is made.

The regulatory environment surrounding waste treatment plants is continually evolving, with increasing emphasis on safety and environmental protection. Composite steel grating can assist facilities in meeting these stringent regulations, as its properties often exceed the standards set forth by governing bodies. This compliance can enhance the reputation of the facility and instill confidence in stakeholders.

Training and education for staff on the proper use and maintenance of composite steel grating are crucial. By ensuring that employees understand the benefits and features of this material, plant operators can maximize its potential and ensure a safe working environment. Regular training sessions can also address any concerns or questions that may arise over time.

The global market for composite steel grating is expanding, driven by the increasing demand for efficient waste treatment solutions. As more municipalities and industries recognize the benefits of this material, the adoption rates are expected to rise. This trend presents opportunities for manufacturers and suppliers to innovate and develop new products tailored to the needs of waste treatment facilities.

উপসংহারে, যৌগিক ইস্পাত ঝাঁঝরি for waste treatment plants represents a significant advancement in the field of wastewater management. Its combination of lightweight design, corrosion resistance, safety features, and cost-effectiveness makes it an ideal choice for modern facilities. As the industry continues to evolve, the role of composite materials will likely become even more prominent, paving the way for more sustainable and efficient waste treatment solutions.