Fabricating steel grating in a garage can be an exciting and rewarding project for DIY enthusiasts and professionals alike. This process not only allows you to create custom solutions for various applications but also helps you develop valuable skills in metalworking. Dalam artikel ini, we will explore the steps involved in fabricating steel grating in a garage, the tools and materials needed, and some tips to ensure a successful outcome.

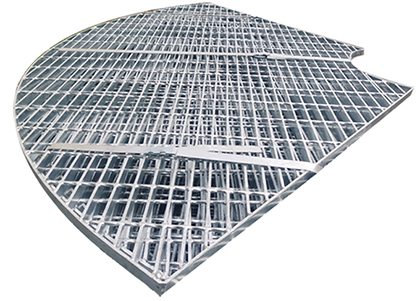

Before diving into the fabrication process, it’s essential to understand what steel grating is and its various applications. Steel grating is a framework of parallel bars or rods that are welded together to form a grid-like structure. It is commonly used in industrial settings for flooring, pelantar kayu dan penutup tanah simen, and drainage covers, providing strength and durability while allowing for drainage and ventilation. Understanding the purpose of your steel grating will guide you in determining the specifications for your project.

To fabricate steel grating in a garage, you will need a variety of tools and materials. Essential tools include a welding machine, cutting tools, and safety equipment such as gloves, goggles, and a welding helmet. For materials, you will require steel bars or rods, which can be purchased from a local metal supplier. The size and thickness of the steel will depend on the intended use of the grating, so be sure to plan accordingly before purchasing your materials.

Once you have gathered your tools and materials, the next step is to create a design for your steel grating. This involves determining the dimensions, spacing, and layout of the bars. A well-thought-out design is crucial for ensuring the functionality and aesthetic appeal of the grating. You can sketch your design on paper or use design software for a more precise representation. Make sure to consider factors such as load-bearing capacity and drainage requirements in your design.

After finalizing your design, it’s time to cut the steel bars to the desired lengths. Using a cutting tool, carefully measure and cut each piece according to your design specifications. Precision is key during this step, as any inaccuracies can affect the overall fit and performance of the grating. Always remember to wear appropriate safety gear while cutting to protect yourself from metal shards and sparks.

With all the steel pieces cut to size, the next step is to assemble the grating. Start by laying out the cut pieces on a flat surface according to your design. Ensure that the spacing between the bars is consistent and matches your design. Once you are satisfied with the layout, you can begin welding the bars together. This process requires skill and attention to detail, as strong welds are essential for the durability of the grating.

When welding, it is important to maintain a steady hand and a consistent speed to create strong, even welds. Begin by tacking the bars in place at the corners to hold everything together. Once the pieces are secured, you can proceed to weld along the seams, ensuring that each joint is fully fused. Allow the welds to cool before moving on to the next step, as this will help prevent warping or distortion of the steel.

After the welding process is complete, you may want to grind down any rough edges or welds to create a smooth finish. This not only enhances the appearance of the steel grating but also helps prevent injuries from sharp edges. Using a grinder, carefully smooth out any imperfections while wearing protective gear to safeguard against debris and sparks.

Once the grating is ground to your satisfaction, it is time to clean and prepare the surface for finishing. This step is crucial for ensuring proper adhesion if you plan to paint or coat the grating. Use a wire brush or sandblaster to remove any rust, dirt, or grease from the surface. A clean surface will help improve the longevity of any protective coatings applied later.

After cleaning, you can choose to apply a finish to your steel grating. This could be a coat of paint, a rust-inhibiting primer, or a specialized coating designed for metal surfaces. Applying a finish not only enhances the appearance of the grating but also provides protection against corrosion and wear. Be sure to follow the manufacturer’s instructions for the best results, and allow sufficient drying time before using the grating.

Now that your steel grating is fabricated and finished, it’s time to install it in its intended location. Depending on the application, you may need to secure the grating to a frame or support structure. Use appropriate fasteners, such as bolts or screws, to ensure a stable installation. If the grating is intended for heavy loads, make sure to consult load ratings and guidelines to ensure safety and functionality.

Ringkasnya, fabricating steel grating in a garage is a multi-step process that requires careful planning, precision, and attention to detail. By following the steps outlined in this article, you can create custom steel grating that meets your specific needs. Whether for industrial use or personal projects, the skills you develop during this process will be invaluable for future metalworking endeavors.

As you gain experience in fabricating steel grating, you may want to explore more complex designs and applications. Consider experimenting with different types of steel, such as stainless steel or galvanized steel, to enhance the properties of your grating. Additionally, you can explore various patterns and configurations to create unique and functional designs that stand out.

Safety should always be a top priority when working with metal and welding equipment. Ensure that your garage workspace is well-ventilated and free of flammable materials. Keep a fire extinguisher nearby, and always wear appropriate safety gear to protect yourself from potential hazards.

Kesimpulannya, fabricating steel grating in a garage is a fulfilling project that combines creativity with practical skills. By understanding the materials, tools, and techniques involved, you can create durable and functional grating that serves a variety of purposes. Whether you are a seasoned metalworker or a beginner, this project offers an excellent opportunity to enhance your skills and produce something valuable.

As you complete your project, consider documenting the process through photos or videos. This can serve as a valuable reference for future projects and can also be shared with others who may be interested in learning how to fabricate steel grating in a garage. Sharing your experiences can inspire others and foster a community of DIY metalworkers eager to learn and create.

akhir sekali, remember that practice makes perfect. The more you work with steel and welding techniques, the more proficient you will become. Don’t be afraid to take on new challenges and push the boundaries of your skills. With dedication and persistence, you can master the art of fabricating steel grating and other metal projects in your garage.