Floor plate steel grating for garage workshops is an essential component that combines durability with functionality. These gratings are designed to withstand heavy loads while providing excellent drainage and ventilation. In garage workshops, where tools and machinery are frequently used, having a reliable flooring solution is crucial for safety and efficiency.

One of the primary benefits of using floor plate steel grating for garage workshops is its ability to support heavy equipment. Unlike traditional flooring options, steel grating can handle the weight of various tools, vehicles, and machinery without warping or cracking. This resilience makes it an ideal choice for both professional and DIY workshops.

In addition to strength, floor plate steel grating for garage workshops offers superior drainage capabilities. The open design allows for easy water runoff, preventing puddles that can lead to slips and falls. This feature is particularly important in a workshop environment where spills are common, ensuring a safer workspace.

Ventilation is another critical aspect of garage workshops, and steel grating excels in this area as well. The spaces between the grating allow for air circulation, reducing the buildup of fumes and heat. Proper ventilation is vital for maintaining a comfortable working environment, especially when using power tools or chemicals.

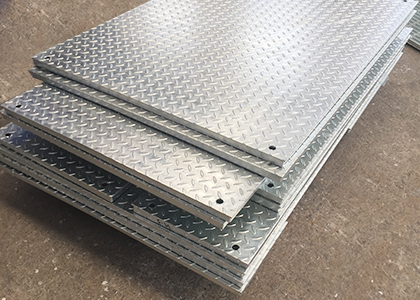

When considering floor plate steel grating for garage workshops, it’s essential to choose the right type of steel. Galvanized steel is often preferred due to its corrosion resistance, which is particularly beneficial in environments where moisture is present. This durability extends the lifespan of the grating, making it a cost-effective choice in the long run.

Installation of floor plate steel grating for garage workshops is straightforward, but it requires careful planning. انسٽاليشن کان اڳ, it’s important to assess the specific needs of the workshop, including load-bearing requirements and drainage needs. This assessment will help determine the appropriate size and spacing of the grating panels.

Maintenance of floor plate steel grating is relatively simple. Regular cleaning can help prevent debris buildup and ensure optimal drainage. اضافي طور تي, periodic inspections can identify any signs of wear or damage, allowing for timely repairs and prolonging the life of the flooring.

جماليات جي لحاظ سان, floor plate steel grating for garage workshops can be finished in various ways. While many choose the raw steel look for its industrial appeal, painting or coating the grating can enhance its appearance and provide additional protection against corrosion. This versatility allows workshop owners to customize their space according to personal preferences.

Cost is always a consideration when choosing flooring for garage workshops. While the initial investment in floor plate steel grating may be higher than traditional flooring options, the long-term benefits often outweigh the costs. Its durability, low maintenance, and safety features contribute to significant savings over time.

Another advantage of floor plate steel grating for garage workshops is its eco-friendliness. Steel is a recyclable material, and choosing steel grating contributes to sustainability efforts. اضافي طور تي, its longevity reduces the need for frequent replacements, further minimizing environmental impact.

For those looking to enhance their garage workshops, floor plate steel grating can be combined with other flooring solutions. مثال طور, rubber mats can be placed in specific areas for added comfort and slip resistance. This combination allows for a tailored approach to workshop flooring, meeting various needs and preferences.

Safety is paramount in any workshop, and floor plate steel grating helps to achieve this goal. The slip-resistant surface of the grating minimizes the risk of accidents, making it a preferred choice for busy work environments. Ensuring that workers feel safe while they operate machinery is crucial for productivity and morale.

When selecting floor plate steel grating for garage workshops, it’s important to consider the load ratings. Different types of grating are designed to support varying weights, so understanding the specific requirements of your workshop is essential. Consulting with a supplier can provide valuable insights into the best options available.

The installation process for floor plate steel grating typically involves securing the panels to a solid substrate. This can be done using screws or welding, depending on the specific application and the type of grating used. Proper installation is key to ensuring that the grating performs as intended and maintains its structural integrity.

For those who prefer a DIY approach, installing floor plate steel grating can be a rewarding project. With the right tools and materials, workshop owners can create a durable and functional flooring solution that meets their specific needs. Online tutorials and guides can provide step-by-step instructions to assist in the installation process.

In addition to traditional garage workshops, floor plate steel grating is also suitable for various other applications. This includes commercial garages, industrial facilities, and even outdoor workspaces. Its versatility makes it a popular choice across different industries, further highlighting its practicality.

As with any flooring material, the choice of floor plate steel grating for garage workshops should also consider the local climate. In areas with high humidity or extreme temperatures, selecting the appropriate steel type and finish can enhance performance and longevity. Understanding environmental factors is crucial for optimal flooring solutions.

For workshop owners who prioritize aesthetic appeal, floor plate steel grating can be customized to fit different design themes. Whether aiming for a modern industrial look or a more traditional workshop feel, the versatility of steel grating allows for creative expression in workspace design.

Finally, investing in high-quality floor plate steel grating for garage workshops is a decision that pays off in the long run. Its combination of durability, حفاظتي, and functionality makes it an ideal flooring solution for anyone serious about their workshop. Ensuring that the workspace is not only practical but also visually appealing can enhance the overall workshop experience.