Floor plate steel grating for loading docks is an essential component in various industrial settings. These grates provide a safe and sturdy surface for heavy loads, ensuring that loading and unloading operations can be conducted efficiently. The durability and strength of steel grating make it a preferred choice for many businesses that require reliable flooring solutions.

One of the primary benefits of using floor plate steel grating for loading docks is its ability to withstand heavy loads. This type of grating is designed to support the weight of forklifts, trucks, and other heavy machinery that are commonly used in loading docks. The robust construction of steel grating ensures that it does not warp or bend under pressure, providing a long-lasting solution for high-traffic areas.

In addition to its strength, floor plate steel grating for loading docks also offers excellent drainage capabilities. The open design of the grating allows water, debris, and other materials to pass through easily, preventing the accumulation of liquids that can create hazardous conditions. This feature is particularly important in environments where spills may occur, as it helps maintain a safe working environment.

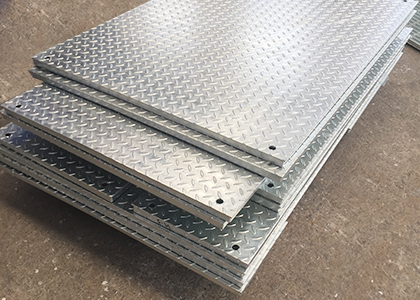

Another advantage of floor plate steel grating for loading docks is its slip-resistant surface. Many grating options come with a textured finish that enhances traction, reducing the risk of slips and falls. This is crucial in busy loading dock areas where employees are constantly moving heavy loads and navigating through tight spaces.

When selecting floor plate steel grating for loading docks, it is essential to consider the specific needs of your operation. Different industries may have varying requirements based on the type of loads being handled and the environmental conditions present. For instance, food processing facilities may require grating that meets specific hygiene standards, while chemical plants may need materials that resist corrosion.

Installation of floor plate steel grating for loading docks is a straightforward process, but it is crucial to ensure that it is done correctly to maximize safety and efficiency. Proper installation involves securing the grating to the underlying structure, ensuring that it is level and stable. This can prevent accidents and prolong the life of the grating, making it a worthwhile investment.

Maintenance of floor plate steel grating is relatively simple. Regular inspections should be conducted to check for any signs of wear or damage. Cleaning the grating periodically can also help maintain its appearance and functionality, particularly in environments where spills or debris are common. Using a pressure washer or industrial cleaning solution can effectively remove stubborn dirt and grime.

The versatility of floor plate steel grating for loading docks extends beyond just industrial applications. It can also be used in commercial settings, such as warehouses and distribution centers. The ability to customize the size and design of the grating allows businesses to create tailored solutions that meet their specific operational needs.

Cost is often a significant factor when choosing floor plate steel grating for loading docks. While steel grating may have a higher upfront cost compared to other materials, its durability and longevity often make it a more economical choice in the long run. Businesses can save on replacement and maintenance costs by investing in high-quality grating that stands the test of time.

In terms of aesthetics, floor plate steel grating for loading docks can be finished in various ways to match the branding and design of a facility. Powder coating, 例如, can provide an additional layer of protection while allowing for color customization. This can enhance the overall appearance of the loading dock area, making it more visually appealing to clients and employees alike.

Environmental considerations are becoming increasingly important in industrial settings. Many manufacturers of floor plate steel grating for loading docks are now focusing on sustainable practices, such as using recycled materials and eco-friendly coatings. By choosing grating from responsible sources, businesses can contribute to environmental conservation while still meeting their operational needs.

Safety regulations in many industries mandate the use of specific flooring materials in loading dock areas. Floor plate steel grating for loading docks typically meets these safety standards, ensuring compliance with local and national regulations. This can help businesses avoid potential fines and legal issues while providing a safe working environment for employees.

The installation of floor plate steel grating can also enhance the overall functionality of a loading dock. By creating a clear and organized workspace, businesses can improve efficiency and productivity. Employees can maneuver more easily, and the risk of accidents is minimized, leading to a smoother workflow.

When considering floor plate steel grating for loading docks, it is also essential to evaluate the long-term benefits. The initial investment in high-quality grating can lead to significant savings over time due to reduced maintenance and replacement costs. Additionally, the safety and efficiency improvements can positively impact overall operations, contributing to a healthier bottom line.

In conclusion, floor plate steel grating for loading docks is a vital component for any industrial or commercial operation that requires a durable and safe flooring solution. Its strength, slip resistance, and drainage capabilities make it an ideal choice for high-traffic areas. By investing in quality grating and ensuring proper installation and maintenance, businesses can create a safer and more efficient loading dock environment that supports their operational goals.

For businesses looking to enhance their loading dock operations, choosing the right flooring solution is crucial. Floor plate steel grating for loading docks not only meets safety and durability requirements but also provides a cost-effective solution for long-term use. By understanding the benefits and features of this type of grating, businesses can make informed decisions that will positively impact their operations.

As industries continue to evolve, the demand for reliable flooring solutions will only increase. Floor plate steel grating for loading docks will remain a staple in many sectors, providing the strength and safety needed for efficient loading and unloading processes. Investing in this type of grating is a proactive approach to ensuring a safe and productive working environment.

In summary, the choice of floor plate steel grating for loading docks is not merely a matter of preference but a strategic decision that can influence the overall efficiency and safety of loading operations. By understanding the various advantages and considerations associated with this flooring option, businesses can better prepare themselves for the demands of modern industrial environments.