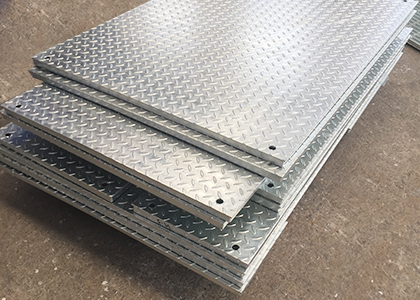

Floor plate steel grating for ramp surfaces is an essential component in modern construction and design. This type of grating is specifically engineered to provide a safe, ti o tọ, and slip-resistant surface for ramps, making it ideal for various applications including commercial and industrial settings. With its robust structure, Fife ilẹ ilẹ ilẹ ensures that ramps can withstand heavy loads and frequent use, which is crucial for maintaining safety in high-traffic areas.

One of the primary advantages of using floor plate steel grating for ramp surfaces is its ability to enhance traction. The surface design typically features raised patterns or serrations that improve grip, dinku eewu ti awọn yiyọ ati ṣubu. This is particularly important in environments where moisture or debris may accumulate, making surfaces slippery. Siwaju sii, the open design of the grating allows for effective drainage, preventing water pooling and further enhancing safety.

In addition to safety, floor plate steel grating for ramp surfaces offers significant durability. Constructed from high-quality steel, this grating can endure harsh weather conditions, heavy machinery, and constant foot traffic without compromising its structural integrity. This durability translates into lower maintenance costs and longer lifespan compared to other materials, making it a cost-effective solution for ramp construction.

Ilana fifi sori ẹrọ fun Plate ilẹ-ilẹ jẹ ki o jinlẹ taara, eyiti o jẹ idi miiran fun gbaye-olokiki rẹ. Contractors can easily cut and shape the grating to fit specific ramp dimensions, ensuring a precise fit that meets safety standards. Ni afikun, the lightweight nature of the grating allows for easier handling and installation, reducing labor costs and time on site.

Another factor to consider when choosing floor plate steel grating for ramp surfaces is its versatility. Available in various sizes, thicknesses, and finishes, this grating can be tailored to match the aesthetic and functional requirements of any project. Whether for a sleek, modern look or a more industrial appearance, floor plate steel grating can be customized to meet design specifications while maintaining its performance characteristics.

Environmental concerns are increasingly influencing construction material choices, and floor plate steel grating is a sustainable option. Steel is a fully recyclable material, which means that at the end of its lifespan, the grating can be repurposed rather than ending up in a landfill. This aligns with the growing demand for sustainable building practices and can contribute to a project’s overall green certification.

When considering floor plate steel grating for ramp surfaces, it’s essential to evaluate the load requirements of the specific application. Different types of grating are designed to support varying weight capacities, ensuring that they can handle the expected traffic without bending or breaking. Consulting with a structural engineer can help determine the appropriate type of grating needed for a particular ramp.

In addition to load capacity, the choice of finish for floor plate steel grating can impact its performance and longevity. Options such as galvanized or powder-coated finishes provide additional protection against corrosion and wear, extending the life of the grating in outdoor or harsh environments. These finishes not only enhance durability but also offer aesthetic benefits, allowing for a more polished appearance.

Safety regulations and codes must also be taken into account when selecting floor plate steel grating for ramp surfaces. Many regions have specific guidelines regarding the design and materials used for ramps, especially in public spaces. Ensuring compliance with these regulations is crucial for avoiding legal issues and ensuring the safety of all users.

Another important consideration is the maintenance of floor plate steel grating. While this material is known for its durability, regular inspections and maintenance can help identify any wear or damage early on. Keeping the grating clean and free from debris will also help maintain its slip-resistant properties, ensuring continued safety for users.

The cost of floor plate steel grating for ramp surfaces can vary based on several factors, including material thickness, finish, and customizations. While it may be more expensive upfront compared to other materials, the long-term benefits of durability, ailewu, and low maintenance costs often justify the investment. Budgeting for this material should take into account both initial costs and potential savings over time.

For those looking to install floor plate steel grating on ramps, there are several suppliers and manufacturers to consider. It’s advisable to research and compare options to find a reputable provider that offers quality products and reliable customer service. Ni afikun, reading reviews and seeking recommendations can help ensure a satisfactory purchasing experience.

The manufacturing process of floor plate steel grating involves several steps, including cutting, shaping, and finishing the steel. Advanced techniques such as laser cutting and CNC machining are often employed to achieve precise dimensions and high-quality finishes. Understanding the manufacturing process can provide insights into the quality and performance of the grating being purchased.

When it comes to design, floor plate steel grating can be integrated into various architectural styles. Its industrial aesthetic can complement modern designs, while its functionality makes it suitable for traditional settings as well. Designers and architects can leverage the versatility of this material to create ramps that are not only practical but also visually appealing.

Ni paripari, floor plate steel grating for ramp surfaces is a vital component in ensuring safety and durability in various environments. Its slip-resistant properties, ease of installation, and versatility make it an excellent choice for both commercial and residential applications. As the demand for high-quality construction materials continues to grow, floor plate steel grating stands out as a reliable option for ramp surfaces.

As we look to the future, innovations in steel grating technology may further enhance the performance and sustainability of floor plate steel grating for ramp surfaces. Continued research and development in material science could lead to even stronger and lighter options, making ramps safer and more efficient to construct. Keeping abreast of these advancements will be essential for industry professionals.

Tikẹhin, the choice of floor plate steel grating for ramp surfaces should be informed by a thorough understanding of the specific needs of the project. Nipa considering awọn okunfa bii agbara fifuye, safety regulations, ati ikolu ayika, stakeholders can make informed decisions that lead to successful outcomes. Pẹlu ọna ti o tọ, floor plate steel grating can provide lasting benefits for years to come.

Ni soki, Fife ilẹ ilẹ ilẹ for ramp surfaces is not just a functional element but a critical aspect of modern construction. Its ability to combine safety, agbara, and aesthetic appeal makes it a preferred choice for architects, contractors, and building owners alike. As we continue to prioritize safety and efficiency in design, floor plate steel grating will undoubtedly remain a key player in the industry.