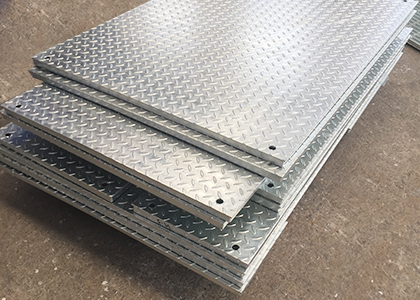

Floor plate steel grating for ship decks is an essential component in maritime construction, providing safety and durability. This type of grating is specifically designed to withstand the harsh marine environment, ensuring longevity and reliability. The unique properties of steel grating make it an ideal choice for ship decks, where strength and stability are paramount.

One of the primary benefits of using floor plate steel grating for ship decks is its slip-resistant surface. This feature is crucial in preventing accidents on wet or oily surfaces, making it a preferred option for many shipbuilders. Additionally, the open design of the grating allows for efficient drainage, further enhancing safety on board.

The manufacturing process of floor plate steel grating involves hot-dip galvanization, which provides a protective coating against corrosion. This process not only extends the life of the grating but also reduces maintenance costs for ship operators. By investing in high-quality steel grating, shipbuilders can ensure that their vessels remain in peak condition for years to come.

When selecting floor plate steel grating for ship decks, it is vital to consider the load-bearing capacity. Different vessels have varying requirements based on their size and intended use. Therefore, consulting with manufacturers about the specific needs of a ship is essential to ensure optimal performance and safety.

Another significant aspect of floor plate steel grating is its lightweight nature. Compared to solid plates, grating offers substantial weight savings without compromising strength. This is particularly important in ship design, where weight distribution can affect stability and fuel efficiency.

In addition to safety and durability, floor plate steel grating for ship decks is also environmentally friendly. Many manufacturers utilize recycled steel in their production processes, contributing to sustainable practices within the maritime industry. This not only benefits the environment but also appeals to eco-conscious shipbuilders and operators.

The versatility of floor plate steel grating allows it to be used in various applications beyond ship decks. It can be employed in walkways, ਪੌੜੀ ਬੋਰਡ, and even in industrial settings. This adaptability makes it a valuable asset for any maritime project, providing a robust solution for multiple needs.

Proper installation of floor plate steel grating is crucial for maximizing its benefits. It is essential to follow manufacturer guidelines and industry standards to ensure a secure fit and optimal performance. Regular inspections and maintenance should also be conducted to identify any wear or damage that may compromise safety.

In terms of design, floor plate steel grating can be customized to fit specific dimensions and configurations. This flexibility allows shipbuilders to create tailored solutions that meet the unique requirements of their vessels. Whether for cargo holds, engine rooms, or outdoor decks, customized grating is available to suit any need.

The aesthetics of floor plate steel grating should not be overlooked. While functionality is paramount, the appearance of a ship’s deck can also impact its overall design. Manufacturers offer various finishes and coatings to enhance the visual appeal of the grating, allowing it to blend seamlessly with the ship’s design.

Cost is a significant factor when considering floor plate steel grating for ship decks. While initial investment may be higher than alternative materials, the long-term savings in maintenance and replacement costs make it a wise choice. Ship operators should evaluate the total cost of ownership when making their decision.

In conclusion, floor plate steel grating for ship decks is an indispensable element in maritime construction. Its combination of safety, durability, and versatility makes it a top choice for shipbuilders worldwide. By understanding the benefits and considerations associated with this material, ship operators can make informed decisions that enhance their vessels’ performance and safety.

As the maritime industry continues to evolve, so too does the technology behind floor plate steel grating. Innovations in manufacturing and materials science are leading to even more advanced grating solutions. Staying informed about these developments can help shipbuilders stay competitive and ensure they are using the best materials available.

The future of floor plate steel grating for ship decks looks promising, with ongoing research and development aimed at improving its properties. This includes enhancing corrosion resistance, increasing load-bearing capabilities, and reducing weight. Such advancements will further solidify the role of steel grating in modern shipbuilding.

Shipbuilders are increasingly recognizing the importance of integrating safety features into their designs. As a result, the demand for floor plate steel grating with enhanced slip resistance and drainage capabilities is on the rise. This trend reflects a broader commitment to safety within the maritime industry.

Collaboration between manufacturers and shipbuilders is essential for the continued success of floor plate steel grating. By working together, these parties can develop innovative solutions that meet the evolving needs of the industry. This partnership will ultimately lead to safer and more efficient vessels.

Training and education on the proper use and maintenance of floor plate steel grating are vital for ship crews. Ensuring that all personnel understand the importance of this material and how to care for it can significantly impact safety and longevity. Regular training sessions can help reinforce these practices and promote a culture of safety.

In summary, floor plate steel grating for ship decks offers numerous advantages that contribute to the overall safety and efficiency of maritime operations. By choosing this material, shipbuilders can ensure that their vessels are equipped with the best solutions available for deck construction. As the industry continues to innovate, the role of floor plate steel grating will only become more significant in the years to come.