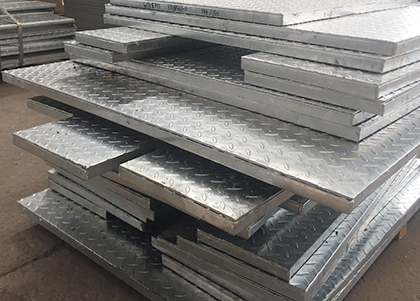

Floor plate steel grating for warehouse floors is an essential component in modern industrial settings. These grates are designed to provide a sturdy surface that can withstand heavy loads while allowing for excellent drainage and ventilation. The use of floor plate steel grating is particularly prevalent in warehouses, where the need for durable and reliable flooring solutions is paramount.

One of the primary benefits of using floor plate steel grating for warehouse floors is its strength and durability. Diperbuat daripada keluli berkualiti tinggi, these grates can support significant weight, making them ideal for areas where heavy machinery and equipment are used. Selain itu, the design of the grating allows for easy installation and maintenance, ensuring that warehouse operations can continue with minimal disruption.

In addition to strength, floor plate steel grating offers safety features that are crucial in a warehouse environment. The open design of the grating provides excellent slip resistance, reducing the risk of accidents caused by wet or oily surfaces. This is especially important in warehouses where workers are constantly moving around, often carrying heavy loads or operating machinery.

Another advantage of floor plate steel grating is its versatility. It can be used in various applications, from walkways and platforms to drainage covers and loading docks. This adaptability makes it a preferred choice for many warehouse managers looking to optimize their space and enhance operational efficiency.

The installation process for floor plate steel grating is relatively straightforward. Typically, it involves measuring the area where the grating will be placed, cutting the steel to the appropriate size, and securing it in place using bolts or welding. This ease of installation not only saves time but also reduces labor costs, making it a cost-effective solution for warehouse flooring.

Maintenance of floor plate steel grating is minimal, which is another reason for its popularity in warehouses. Regular inspections can help identify any wear and tear, but generally, the steel grating is resistant to corrosion and damage. Periodic cleaning is usually sufficient to keep the grating in optimal condition, ensuring longevity and performance.

In terms of aesthetics, floor plate steel grating can be customized to fit the specific needs of a warehouse. Different finishes and coatings can be applied to enhance the appearance and further protect against corrosion. This customization allows warehouse managers to maintain a professional look while ensuring functionality and safety.

When considering floor plate steel grating for warehouse floors, it is essential to evaluate the load-bearing requirements. Different types of grating are available, each designed to support varying weights. Consulting with a supplier can help in selecting the right type of grating that meets the specific demands of the warehouse environment.

Selain itu, integrating floor plate steel grating with other flooring solutions can enhance the overall functionality of a warehouse. For instance, combining grating with solid flooring sections can create designated areas for heavy machinery while maintaining open spaces for pedestrian traffic. This hybrid approach can optimize workflow and safety.

The environmental impact of using floor plate steel grating is also worth noting. Steel is a recyclable material, and many manufacturers prioritize sustainability in their production processes. By choosing floor plate steel grating, warehouse managers can contribute to eco-friendly practices while ensuring a robust flooring solution.

Kesimpulannya, floor plate steel grating for warehouse floors is an excellent investment for any industrial facility. Gabungan kekuatannya, safety, Fleksibiliti, and low maintenance makes it a top choice for warehouse flooring. As businesses continue to evolve, the demand for reliable flooring solutions like steel grating will only increase, making it a vital component of modern warehouse design.

Furthermore, the cost-effectiveness of floor plate steel grating cannot be overlooked. While the initial investment may seem significant, the long-term savings in maintenance and replacement costs make it a wise choice for warehouse managers. Investing in quality materials ensures that the flooring will last for years, providing a solid return on investment.

The installation of floor plate steel grating can also enhance the overall efficiency of warehouse operations. With a sturdy and reliable surface, workers can move more freely and quickly, reducing downtime and increasing productivity. This efficiency translates to better overall performance for the warehouse as a whole.

Another consideration when selecting floor plate steel grating is the load distribution. Properly designed grating will distribute weight evenly across the surface, preventing localized stress points that can lead to structural failure. This is particularly important in warehouses where heavy loads are frequently moved around.

In addition to load distribution, the design of floor plate steel grating allows for effective drainage. The open spaces between the grating facilitate the quick removal of liquids, preventing pooling and reducing slip hazards. This is especially beneficial in environments where spills are common, such as warehouses dealing with chemicals or food products.

Selain itu, floor plate steel grating can be integrated with other safety features in a warehouse. Adding guardrails or safety nets can further enhance worker protection, especially in areas where there is a risk of falling. This comprehensive approach to safety ensures a secure working environment for all employees.

The longevity of floor plate steel grating is another critical factor to consider. With proper maintenance, these grates can last for decades, providing a reliable flooring solution without the need for frequent replacements. This durability is a significant advantage for warehouse managers looking to minimize disruptions and maximize efficiency.

In terms of design flexibility, floor plate steel grating can be tailored to fit various warehouse layouts. Custom sizes and configurations can be created to accommodate unique spaces, ensuring that every inch of the warehouse floor is utilized effectively. This adaptability is crucial for optimizing workflow and storage capacity.

Finally, as technology advances, the manufacturing processes for floor plate steel grating continue to improve. Innovations in steel production and coating techniques enhance the performance and lifespan of grating products. Warehouse managers can benefit from these advancements by selecting the latest grating solutions available in the market.