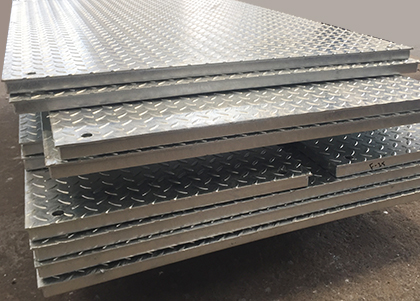

Floor plate steel grating for workshop benches is a vital component in many industrial and commercial settings. These grates provide a durable and reliable surface for workstations, ensuring safety and efficiency. The design of floor plate steel grating allows for excellent drainage and airflow, making it ideal for workshops where spills and debris are common.

One of the primary benefits of using floor plate steel grating for workshop benches is its strength. Made from high-quality steel, these gratings can withstand heavy loads and resist deformation over time. This durability is crucial in a workshop environment where tools and materials are frequently moved around.

Another significant advantage of floor plate steel grating is its slip-resistant surface. This feature is particularly important in workshops where workers may be exposed to wet or oily conditions. The textured surface of the grating helps to prevent slips and falls, contributing to a safer workplace.

In addition to safety, floor plate steel grating for workshop benches is also easy to clean and maintain. The open design allows for easy removal of debris and spills, making it a practical choice for busy work environments. Regular cleaning can help maintain the integrity of the grating and prolong its lifespan.

When selecting floor plate steel grating for workshop benches, it is essential to consider the specific needs of your workspace. Factors such as load capacity, dimensions, and the type of materials being used should all be taken into account. This ensures that the grating will perform effectively in your particular setting.

The installation of floor plate steel grating is a straightforward process that can often be completed with minimal tools. Many manufacturers provide detailed instructions to assist with the installation, ensuring that the grating is securely fastened and properly aligned. This ease of installation is a significant advantage for workshop managers looking to upgrade their workspaces.

Customization options for floor plate steel grating are also available, allowing businesses to tailor the product to their specific requirements. This can include adjustments in size, แพลตฟอร์มการบำรุงรักษา, and even coating options to enhance corrosion resistance. Customization ensures that the grating fits perfectly within the designated area and meets the unique demands of the workshop.

In terms of aesthetics, floor plate steel grating can be finished in various ways to match the overall design of the workshop. While functionality is paramount, a visually appealing workspace can also contribute to employee morale and productivity. Choosing the right finish can help create a cohesive look throughout the workshop.

The environmental impact of floor plate steel grating is another consideration for modern workshops. Many manufacturers are now focusing on sustainable practices, using recycled materials and eco-friendly coatings. This not only reduces the carbon footprint of the product but also appeals to businesses looking to enhance their sustainability efforts.

Cost-effectiveness is a critical factor when selecting floor plate steel grating for workshop benches. While the initial investment may seem high, the long-term benefits of durability, safety, and low maintenance costs make it a wise choice. Over time, the return on investment becomes evident as the grating outlasts cheaper alternatives.

In addition to workshops, floor plate steel grating is also suitable for various applications beyond benches. It can be used in platforms, พื้นผิวลื่นและสภาพแวดล้อมที่รุนแรงอื่นๆ, and even as flooring in industrial settings. This versatility makes it a popular choice among contractors and builders looking for reliable materials.

The manufacturing process of floor plate steel grating involves several steps, including cutting, welding, and finishing. Understanding this process can help businesses appreciate the quality of the product they are purchasing. High-quality manufacturing practices ensure that the grating meets industry standards and performs as expected.

Regular inspections of floor plate steel grating are recommended to ensure its continued safety and performance. This includes checking for signs of wear, corrosion, or damage. By addressing any issues promptly, businesses can prevent accidents and maintain a safe working environment.

Training employees on the proper use and maintenance of floor plate steel grating is essential. This includes educating them on the importance of keeping the grating clean and free of obstructions. A well-informed workforce is key to maximizing the benefits of this product.

The future of floor plate steel grating is promising, with ongoing advancements in materials and manufacturing techniques. Innovations such as lightweight composites and enhanced coatings are being explored to improve performance further. Staying informed about these developments can help businesses make better purchasing decisions.

In summary, floor plate steel grating for workshop benches is an invaluable asset for any industrial workspace. Its combination of strength, safety, and ease of maintenance makes it a top choice for workshop managers. By investing in high-quality grating, businesses can enhance productivity and create a safer working environment for their employees.

When considering the installation of floor plate steel grating, it’s essential to work with reputable suppliers. They can provide guidance on the best products for your specific needs and ensure that you receive quality materials. Building a relationship with a trusted supplier can lead to better service and support in the long run.

The impact of floor plate steel grating extends beyond the workshop itself. By creating safer and more efficient workspaces, businesses can improve overall productivity and employee satisfaction. This, in turn, can lead to increased profitability and growth opportunities.

In conclusion, floor plate steel grating for workshop benches is not just a functional choice; it is a strategic investment in the future of your business. By prioritizing safety, durability, and ease of maintenance, you can create an environment where employees thrive and productivity flourishes.