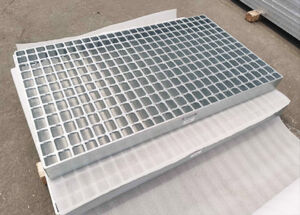

Heavy duty grating for bridge piers is an essential component in modern civil engineering, providing critical support and durability in various bridge designs. These gratings are specifically designed to withstand heavy loads and harsh environmental conditions, making them ideal for use in bridge piers. The importance of selecting the right materials and designs cannot be overstated, as they contribute significantly to the overall safety and longevity of the structure.

When considering heavy duty grating for bridge piers, one must evaluate the different materials available in the market. Common materials include steel, fiberglass, and aluminum, each offering unique advantages and disadvantages. Стали, for instance, is known for its strength and durability, while fiberglass is lightweight and resistant to corrosion, making it suitable for various applications.

One of the primary benefits of using heavy duty grating for bridge piers is its ability to distribute loads evenly across the structure. This load distribution is crucial in preventing localized stress points that could lead to structural failure. Engineers must carefully calculate load requirements to ensure that the selected grating can handle the anticipated stresses over time.

Another significant aspect of heavy duty grating for bridge piers is its role in drainage and water management. Proper drainage is vital in preventing water accumulation around bridge piers, which can lead to erosion and weaken the foundation. Gratings designed with drainage slots or openings facilitate the quick removal of water, enhancing the longevity of the piers.

In addition to load distribution and drainage, heavy duty grating for bridge piers also provides a safe walking surface for maintenance personnel. Many bridge designs require regular inspections and maintenance, and having a robust grating system in place ensures that workers can safely access different parts of the bridge without risking slips or falls. Safety features such as anti-slip surfaces can further enhance the usability of these gratings.

The installation process of heavy duty grating for bridge piers is another critical consideration. Proper installation techniques must be employed to ensure that the gratings are securely fastened and aligned correctly. Engineers and contractors must work together to develop a comprehensive installation plan that adheres to industry standards and regulations, ensuring the safety and effectiveness of the grating system.

Maintenance of heavy duty grating for bridge piers is essential for ensuring the longevity and performance of the structure. Regular inspections should be conducted to identify any signs of wear, corrosion, or damage that could compromise the integrity of the grating. Addressing these issues promptly can prevent more significant problems down the line and extend the lifespan of the bridge.

In recent years, advancements in technology have led to the development of innovative heavy duty grating solutions for bridge piers. For example, new composite materials are being used that offer enhanced strength-to-weight ratios and improved resistance to environmental factors. These innovations are paving the way for more efficient and cost-effective bridge designs that can better withstand the test of time.

Sustainability is also becoming a key consideration in the selection of heavy duty grating for bridge piers. As awareness of environmental issues grows, many engineers are looking for materials that are not only durable but also eco-friendly. Options such as recycled steel and biodegradable composites are gaining popularity, aligning with global efforts to reduce the carbon footprint of construction projects.

The aesthetic aspect of heavy duty grating for bridge piers should not be overlooked. While functionality is paramount, the visual appeal of a bridge can significantly impact its acceptance by the public. Designers are increasingly considering how gratings can complement the overall architectural vision of the bridge, leading to more visually pleasing structures that enhance the surrounding environment.

Cost considerations are always a factor when selecting heavy duty grating for bridge piers. While it may be tempting to opt for the cheapest option available, it is crucial to consider the long-term value of investing in high-quality materials. Cheaper gratings may require more frequent replacements and repairs, ultimately leading to higher costs over time. Engineers must balance initial costs with the projected lifespan and maintenance needs of the grating system.

Case studies of successful heavy duty grating installations for bridge piers can provide valuable insights for engineers and contractors. These examples highlight the challenges faced during installation, the solutions implemented, and the outcomes achieved. Learning from past projects can help inform future designs and improve the overall effectiveness of grating systems in bridge construction.

The role of heavy duty grating for bridge piers in enhancing structural resilience cannot be overstated. As climate change continues to impact weather patterns and increase the frequency of extreme weather events, the need for robust and reliable infrastructure becomes even more critical. Gratings that can withstand such conditions will play a vital role in ensuring the safety and functionality of bridges in the years to come.

Furthermore, collaboration between engineers, architects, and construction teams is essential for the successful implementation of heavy duty grating for bridge piers. Open communication and teamwork can lead to innovative solutions that enhance the design and functionality of the bridge. By working together, these professionals can ensure that all aspects of the project are considered, leading to a more cohesive and efficient outcome.

Training and education on the proper use and installation of heavy duty grating for bridge piers are also crucial. As new materials and technologies emerge, it is vital that industry professionals stay informed about the latest advancements. Workshops, seminars, and online courses can provide valuable resources for engineers and contractors seeking to enhance their knowledge and skills in this area.

In conclusion, heavy duty grating for bridge piers is a multifaceted topic that encompasses a wide range of considerations, from material selection to installation and maintenance. As infrastructure demands continue to grow, the importance of robust and durable grating systems will only increase. By prioritizing quality, safety, and sustainability, engineers can contribute to the development of bridges that stand the test of time and serve their communities effectively.

As we look to the future, the integration of smart technologies into heavy duty grating for bridge piers may become a reality. Sensors embedded within the gratings could provide real-time data on load distribution, temperature changes, and structural integrity. This data could be invaluable for maintenance teams, allowing for proactive measures to be taken before issues arise.

The global market for heavy duty grating for bridge piers is also expanding, with various manufacturers competing to provide the best solutions. As demand grows, so does the need for innovation and improvement in grating design and materials. Companies that invest in research and development will likely lead the industry, setting new standards for quality and performance.

Finally, the role of government regulations and standards cannot be overlooked in the discussion of heavy duty grating for bridge piers. Compliance with local and national guidelines ensures that all materials and installations meet safety and performance criteria. Staying updated on these regulations is essential for engineers and contractors to ensure that their projects are not only effective but also compliant with legal requirements.