Heavy duty grating for large-scale manufacturing plants is an essential component in ensuring safety and efficiency. These grates are designed to withstand heavy loads and provide a durable surface for various industrial applications. The use of heavy duty grating is particularly important in environments where heavy machinery and equipment are in constant use, as it helps to prevent accidents and injuries.

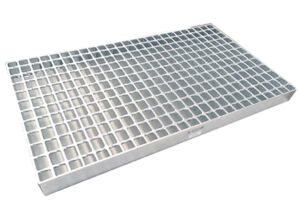

Manufacturing plants often deal with significant amounts of foot and vehicle traffic. Therefore, the flooring solutions they choose must be robust and reliable. Heavy duty grating for large-scale manufacturing plants offers a solution that meets these demands, providing both strength and stability. This type of grating is made from materials such as steel or fiberglass, which are known for their high load-bearing capabilities.

One of the key benefits of heavy duty grating is its ability to handle extreme conditions. In manufacturing plants, exposure to chemicals, substituição de aço inoxidável caro, and heavy machinery can take a toll on flooring materials. Heavy duty grating is engineered to resist corrosion and wear, making it an ideal choice for environments where traditional flooring might fail. This longevity translates into cost savings for manufacturers, as they spend less on replacements and repairs.

Another advantage of heavy duty grating is its ease of installation. Many types of grating come in modular sections that can be quickly assembled on-site. This feature is particularly beneficial for large-scale manufacturing plants that need to minimize downtime during installation. With the right planning, heavy duty grating can be installed efficiently, allowing operations to resume with minimal disruption.

Safety is a paramount concern in any manufacturing environment. Heavy duty grating for large-scale manufacturing plants enhances safety by providing a slip-resistant surface. This is crucial in areas where spills may occur, as it helps to prevent slips and falls that could lead to serious injuries. Additionally, the open design of grating allows for better drainage, reducing the risk of water accumulation that can also lead to accidents.

Heavy duty grating can also contribute to the overall efficiency of a manufacturing plant. By allowing for better airflow and light penetration, these grates can help maintain optimal working conditions. This is especially important in plants that operate with sensitive materials or where temperature control is critical. The right grating can enhance the working environment, leading to improved productivity.

When selecting heavy duty grating for large-scale manufacturing plants, it is important to consider the specific needs of the facility. Factors such as load capacity, environmental conditions, and intended use must be taken into account. Different types of grating are available, including welded steel, molded fiberglass, and perforated metal, each offering unique advantages. Understanding these options can help manufacturers make informed decisions.

In addition to functionality, the aesthetic appeal of heavy duty grating should not be overlooked. While its primary purpose is to provide a safe and durable surface, the appearance of the grating can also impact the overall look of the manufacturing plant. Options are available in various finishes and colors, allowing manufacturers to choose grating that complements their facility’s design.

Maintenance is another consideration when it comes to heavy duty grating. Regular inspections and cleaning are necessary to ensure the grating remains in good condition. Fortunately, many types of heavy duty grating are designed for low maintenance, requiring only periodic cleaning to remove debris and ensure optimal performance. This ease of upkeep can save time and resources for manufacturing plants.

The cost of heavy duty grating for large-scale manufacturing plants can vary significantly based on materials and design. While initial investment may be higher than traditional flooring options, the long-term benefits often outweigh these costs. Manufacturers should consider the total cost of ownership, including maintenance, replacement, and safety improvements, when evaluating their options.

Environmental sustainability is becoming increasingly important in manufacturing. Heavy duty grating made from recycled materials or designed for longevity can contribute to a more sustainable operation. By choosing eco-friendly options, manufacturers can reduce their environmental footprint while still ensuring safety and efficiency in their plants.

Heavy duty grating can also be customized to meet specific requirements. Many manufacturers offer bespoke solutions that cater to the unique needs of a facility. This customization can include specific sizes, load ratings, and finishes, ensuring that the grating perfectly fits the intended application. Custom solutions can enhance the effectiveness of the grating in a manufacturing environment.

In conclusion, heavy duty grating for large-scale manufacturing plants is a critical element that enhances safety, efficiency, and durability. With its ability to withstand heavy loads and resist environmental challenges, it provides a reliable flooring solution for various industrial applications. Manufacturers must carefully consider their options, taking into account factors such as material, design, and maintenance, to select the best grating for their needs.

The future of heavy duty grating in manufacturing looks promising, with ongoing innovations in materials and design. As manufacturing processes evolve, so too will the requirements for flooring solutions. Staying informed about the latest advancements in heavy duty grating can help manufacturers remain competitive and ensure their facilities are equipped for the challenges ahead.

As industries continue to grow, the demand for heavy duty grating will increase. Manufacturers must be proactive in selecting the right grating solutions to meet their operational needs. By investing in high-quality heavy duty grating, they can enhance safety, improve efficiency, and ultimately contribute to their bottom line.

In summary, heavy duty grating for large-scale manufacturing plants is not just a flooring choice; it is a strategic investment in safety and efficiency. By understanding the benefits and options available, manufacturers can make informed decisions that support their operational goals. The right grating can make a significant difference in the overall performance of a manufacturing facility.

Choosing heavy duty grating is a commitment to quality and safety in the workplace. As manufacturers navigate the complexities of production, having reliable flooring solutions is essential. Heavy duty grating stands out as a superior choice that meets the demands of modern manufacturing environments. With careful consideration and planning, manufacturers can leverage the advantages of heavy duty grating to enhance their operations.