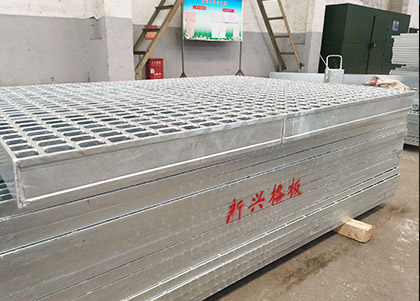

Heavy duty grating for oil refineries is an essential component in ensuring safety and efficiency within the industrial environment. These gratings are designed to withstand the harsh conditions typical of oil refineries, including exposure to chemicals, high temperatures, and heavy loads. The durability and resilience of heavy duty grating make it a preferred choice for many applications, providing a reliable solution for walkways, ligna platformo kaj kovrilo cemento grundo, and drainage systems.

The manufacturing process of heavy duty grating involves high-quality materials and advanced engineering techniques. Typically constructed from steel or fiberglass, these gratings are designed to meet stringent safety standards. The choice of material is crucial, as it affects the grating’s ability to resist corrosion and its overall lifespan in the demanding environment of an oil refinery.

One of the primary benefits of heavy duty grating for oil refineries is its load-bearing capacity. These gratings are engineered to support heavy equipment and personnel, minimizing the risk of structural failure. This is particularly important in areas where heavy machinery operates, as the safety of workers and equipment is paramount.

In addition to load-bearing capabilities, heavy duty grating provides excellent drainage solutions. The design of these gratings allows for efficient water and oil runoff, preventing pooling and potential hazards. This feature is especially critical in oil refineries where spills can lead to dangerous situations and environmental concerns.

Another significant advantage of heavy duty grating is its slip resistance. The surface of the grating can be treated or designed to provide additional traction, which is vital in preventing accidents. In an oil refinery, where spills and leaks are common, ensuring a safe walking surface is essential for worker safety.

Maintenance is another crucial aspect of heavy duty grating for oil refineries. Regular inspections and cleaning can prolong the life of the grating and ensure it continues to function effectively. It is important for refinery operators to establish a maintenance schedule to address any wear and tear that may occur over time.

The installation of heavy duty grating in oil refineries requires careful planning and execution. It is essential to assess the specific needs of the facility and choose the right type of grating that meets those requirements. Factors such as load capacity, chemical resistance, and environmental conditions must be taken into account during this process.

Heavy duty grating is available in various designs and configurations, allowing for customization based on the specific needs of an oil refinery. Common types include welded, swage-locked, and press-locked gratings, each offering unique advantages. The choice of design can impact installation methods and overall performance in the refinery setting.

In terms of cost-effectiveness, investing in heavy duty grating can lead to significant savings in the long run. While the initial investment may be higher compared to standard grating options, the durability and reduced maintenance needs can offset these costs. Refineries can benefit from lower replacement rates and fewer safety incidents, ultimately enhancing their bottom line.

The environmental impact of heavy duty grating is also a consideration for oil refineries. Many manufacturers are now producing gratings from recycled materials, contributing to sustainability efforts in the industry. This shift not only reduces waste but also aligns with the growing emphasis on environmentally friendly practices within the oil and gas sector.

Heavy duty grating can also enhance the aesthetic appeal of an oil refinery. While functionality is the primary concern, the appearance of walkways and platforms can contribute to the overall image of the facility. Modern designs and finishes allow for a balance between safety and visual appeal, making the refinery a more attractive workplace.

In conclusion, heavy duty grating for oil refineries plays a crucial role in ensuring safety, efficiency, and sustainability. Its robust design, load-bearing capacity, and slip-resistant features make it an indispensable component in the oil refining process. As the industry continues to evolve, the demand for high-quality grating solutions will only increase, necessitating ongoing innovation and development.

The selection of heavy duty grating should also consider compliance with industry regulations. Oil refineries are subject to strict safety and environmental standards, and using the right grating can help meet these requirements. Understanding local regulations and guidelines is essential for refinery operators when choosing their grating solutions.

Furthermore, the versatility of heavy duty grating allows it to be used in various applications beyond walkways and platforms. It can also be employed in drainage trenches, equipment supports, and even as protective barriers. This adaptability makes it a valuable asset in any oil refinery, enhancing operational efficiency.

The longevity of heavy duty grating is a key factor for oil refineries. With proper care and maintenance, these gratings can last for decades, providing a reliable solution for critical infrastructure needs. This durability is particularly important in an industry where downtime can result in significant financial losses.

When considering heavy duty grating options, it is advisable to consult with industry experts. Professionals can provide insights into the best materials, designs, and installation techniques tailored to the unique requirements of each refinery. Their expertise can help ensure that the chosen grating solution meets both performance and safety standards.

The role of heavy duty grating in emergency situations cannot be overlooked. In the event of a spill or accident, having a reliable grating system can facilitate quick response and evacuation. This preparedness is vital for minimizing risks and ensuring the safety of personnel and equipment during critical incidents.

Training staff on the proper use and maintenance of heavy duty grating is also essential. Ensuring that employees understand the importance of these systems and how to identify potential issues can enhance the overall safety culture within the refinery. Regular training sessions can reinforce best practices and promote a proactive approach to safety.

In summary, heavy duty grating for oil refineries is more than just a structural element; it is a vital component that supports safety, efficiency, and sustainability. By investing in high-quality grating solutions, refineries can enhance their operations and protect their workforce, ultimately leading to greater success in the competitive oil and gas industry.