Heavy duty grating for ports and harbors is an essential component in maritime infrastructure, providing safety and durability in demanding environments. The unique characteristics of heavy duty grating ensure that it can withstand the harsh conditions found in these areas, including exposure to saltwater, heavy loads, and constant foot and vehicle traffic. This article will explore the various aspects of heavy duty grating, including its materials, applications, and benefits, while maintaining a focus on its critical role in ports and harbors.

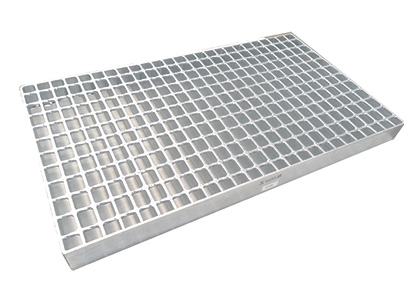

One of the primary materials used in the production of heavy duty grating for ports and harbors is steel. Steel grating offers exceptional strength and resistance to wear, making it ideal for high-traffic areas. উপরন্তু, steel can be treated with coatings or finishes that enhance its corrosion resistance, ensuring a longer lifespan even in challenging marine environments. The choice of material is crucial for ensuring the safety and reliability of the grating in these demanding applications.

Another popular material for heavy duty grating is fiberglass reinforced plastic (FRP). FRP grating is lightweight yet incredibly strong, making it an excellent choice for areas where weight is a concern. Furthermore, FRP is inherently resistant to corrosion, making it suitable for use in ports and harbors where exposure to saltwater is inevitable. The combination of strength and lightweight properties makes FRP an attractive option for many maritime applications.

Heavy duty grating is designed to support various loads, from pedestrian traffic to heavy machinery. In ports and harbors, grating must be able to withstand the weight of trucks, cranes, and containers. This requires careful engineering and design to ensure that the grating can handle these loads without compromising safety. The load-bearing capacity of heavy duty grating is a key factor in its selection for specific applications within maritime settings.

In addition to load capacity, slip resistance is another critical factor in the design of heavy duty grating for ports and harbors. Slippery surfaces can pose significant safety risks, especially in wet environments. Many manufacturers incorporate slip-resistant surfaces into their grating designs, using various textures and patterns to enhance traction. This feature is particularly important in areas where workers are frequently moving heavy equipment or materials, as it helps prevent accidents and injuries.

The installation process for heavy duty grating is another important consideration. Proper installation is crucial to ensuring the longevity and effectiveness of the grating system. This often involves securing the grating to a framework or support structure, which can be made from steel or concrete. উপরন্তু, regular maintenance and inspection are necessary to identify any wear or damage that may occur over time, ensuring that the grating remains safe and functional.

Environmental factors play a significant role in the performance of heavy duty grating for ports and harbors. The marine environment is known for its challenges, including exposure to saltwater, চরম তাপমাত্রা, and heavy winds. These factors can lead to corrosion and deterioration of materials over time. Therefore, selecting the right type of grating and ensuring proper maintenance is essential for maximizing its lifespan and effectiveness in such conditions.

In recent years, there has been a growing trend towards sustainability in the construction and maintenance of ports and harbors. Heavy duty grating made from recycled materials or designed for easy recycling at the end of its life cycle is becoming more popular. This approach not only reduces environmental impact but also aligns with the increasing demand for sustainable practices in the maritime industry. Companies that prioritize sustainability in their operations often find that it enhances their reputation and attracts environmentally conscious clients.

The versatility of heavy duty grating allows it to be used in various applications within ports and harbors. From walkways and loading docks to drainage systems and equipment platforms, the uses are numerous. Each application may require specific design features, such as different load capacities or surface textures, to meet the unique demands of the environment. Understanding the specific needs of each application is vital for selecting the appropriate type of grating.

Heavy duty grating also plays a crucial role in drainage systems within ports and harbors. Proper drainage is essential for preventing water accumulation, which can lead to safety hazards and structural damage. Grating systems can be designed to facilitate water flow while providing a safe walking or driving surface. This dual functionality makes heavy duty grating an integral part of effective drainage solutions in maritime settings.

Safety regulations and standards are critical in the design and implementation of heavy duty grating for ports and harbors. Compliance with these regulations ensures that grating systems meet safety requirements and perform as expected. Manufacturers and contractors must stay informed about the latest standards and best practices to ensure that their products and installations are safe and effective. This commitment to safety helps protect workers and equipment in busy harbor environments.

The cost of heavy duty grating for ports and harbors can vary significantly based on material, design, and application. While initial costs may be a consideration, it is essential to evaluate the long-term benefits of investing in high-quality grating systems. Durability, নিরাপত্তা, and reduced maintenance costs can lead to significant savings over time, making it a wise investment for port authorities and operators.

উপসংহারে, heavy duty grating for ports and harbors is a vital component of maritime infrastructure. Its unique properties, including strength, corrosion resistance, and slip resistance, make it suitable for the demanding conditions found in these environments. By understanding the various materials and applications of heavy duty grating, stakeholders can make informed decisions that enhance safety, efficiency, and sustainability in port operations. As the maritime industry continues to evolve, the importance of high-quality grating systems will only increase, making it an essential topic for ongoing discussion and innovation.

Future developments in heavy duty grating technology may focus on improving materials and designs to enhance performance further. Innovations such as smart grating that incorporates sensors for monitoring wear and safety could revolutionize the industry. উপরন্তু, advancements in manufacturing processes may lead to more efficient production methods, reducing costs and environmental impact. Staying abreast of these trends will be crucial for companies looking to remain competitive in the maritime sector.

Collaboration between manufacturers, port authorities, and engineers is essential for advancing the field of heavy duty grating. By working together, these stakeholders can share insights and best practices, leading to better products and safer installations. This collaborative approach can also drive innovation, as different perspectives can lead to new ideas and solutions for common challenges in the industry.

Training and education for workers involved in the installation and maintenance of heavy duty grating are critical for ensuring safety and effectiveness. Providing comprehensive training programs can equip workers with the knowledge and skills needed to handle grating systems properly. This investment in human resources not only enhances safety but also contributes to the overall efficiency of port operations, as well-trained workers can perform their tasks with confidence and competence.

In summary, heavy duty grating for ports and harbors is a multifaceted topic that encompasses various materials, applications, and considerations. Its importance in ensuring safety, স্থায়িত্ব, and efficiency in maritime operations cannot be overstated. As the industry continues to evolve, ongoing research, collaboration, and innovation will play crucial roles in shaping the future of heavy duty grating systems and their applications in ports and harbors.