Heavy duty grating for power generation plants is an essential component in the infrastructure of modern energy facilities. These gratings provide not only structural support but also safety and accessibility for maintenance personnel. The robust design of heavy duty grating ensures it can withstand the harsh environments typically found in power generation settings, such as high temperatures and heavy loads.

In power generation plants, heavy duty grating is utilized in various applications, including walkways, etc., and drainage systems. The materials used for these gratings are often selected for their durability and resistance to corrosion, which is crucial given the exposure to chemicals and elements. Additionally, the grating allows for efficient drainage, preventing water accumulation that could lead to safety hazards.

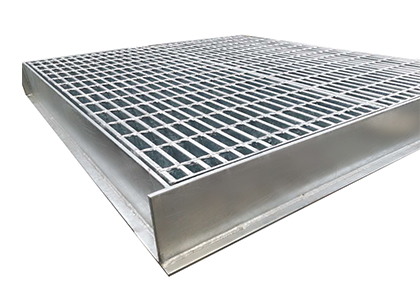

One of the primary materials used in heavy duty grating for power generation plants is steel, often galvanized for added protection against rust. Stainless steel is another popular choice, especially in environments where chemical exposure is a concern. The choice of material impacts not only the lifespan of the grating but also the overall safety of the plant operations.

The design of heavy duty grating must comply with industry standards and regulations, ensuring that it can handle the specific loads and stresses it will encounter. Engineers often conduct load tests to determine the appropriate specifications for the grating, taking into account factors such as foot traffic, equipment weight, and environmental conditions. This meticulous planning helps prevent failures that could lead to operational downtime or accidents.

Another significant advantage of heavy duty grating is its lightweight nature despite its strength. This characteristic makes installation easier and reduces the load on supporting structures. Additionally, the open design of the grating allows for ventilation and light penetration, which is beneficial in maintaining a safe working environment in power generation plants.

Heavy duty grating can also be customized to fit specific dimensions and requirements of a power generation facility. Manufacturers offer various sizes, shapes, and coatings to meet the unique needs of each project. This customization ensures that the grating not only fits perfectly but also enhances the overall aesthetic and functionality of the plant.

Safety is paramount in power generation plants, and heavy duty grating plays a crucial role in ensuring worker safety. The slip-resistant surface of the grating helps prevent accidents, especially in areas prone to spills or wet conditions. Regular inspections and maintenance of the grating are essential to ensure its integrity and safety over time.

In addition to safety, heavy duty grating contributes to the efficiency of power generation plants. By allowing for easy access to machinery and equipment, maintenance personnel can perform their tasks more effectively, reducing downtime and improving overall productivity. The strategic placement of gratings can also facilitate the flow of materials and personnel throughout the facility.

Environmental considerations are becoming increasingly important in power generation, and heavy duty grating can play a role in sustainability efforts. Many manufacturers are now producing gratings from recycled materials, reducing the carbon footprint of new installations. Furthermore, the longevity of heavy duty grating means less frequent replacements, which also contributes to environmental sustainability.

The installation process of heavy duty grating is critical to its performance. Proper alignment and secure fastening are essential to ensure that the grating can withstand the intended loads. Many facilities employ specialized contractors with experience in grating installation to ensure that the job is done correctly and safely.

Maintenance of heavy duty grating is another vital aspect of its lifecycle. Regular inspections should be conducted to identify any signs of wear, corrosion, or damage. Timely repairs or replacements can prevent larger issues from developing, ensuring the continued safety and functionality of the power generation plant.

Heavy duty grating also offers versatility in design, with options for different patterns and configurations. This versatility allows for creative solutions that can enhance the functionality of the plant while also meeting aesthetic preferences. Designers can work with engineers to create custom solutions that fit the specific needs of the facility.

The cost of heavy duty grating for power generation plants can vary significantly based on materials, design, and installation. While upfront costs may be higher for premium materials, the long-term savings associated with durability and reduced maintenance often justify the investment. Facility managers must weigh these factors when budgeting for grating solutions.

Heavy duty grating is not limited to power generation plants; it is also widely used in other industrial applications, including wastewater treatment facilities and chemical plants. The principles of durability and safety apply across these sectors, highlighting the importance of high-quality grating in industrial environments.

As technology advances, the manufacturing processes for heavy duty grating are continually evolving. Innovations in materials and production techniques are leading to even stronger and more lightweight options. This progress is essential as power generation plants seek to improve efficiency and reduce operational costs.

The role of heavy duty grating in emergency response situations cannot be overlooked. In the event of a spill or accident, the grating can provide a stable surface for emergency personnel to navigate. Its design can also facilitate quick drainage, minimizing the impact of hazardous materials on the environment.

Training for personnel on the proper use and maintenance of heavy duty grating is crucial. Ensuring that staff understand the importance of the grating and how to inspect and maintain it can significantly enhance workplace safety. Regular training sessions can keep safety protocols fresh in the minds of employees.

In conclusion, heavy duty grating for power generation plants is a critical component that affects safety, efficiency, and sustainability. Its robust design, material options, and customizable features make it an ideal solution for the demands of the energy industry. As facilities continue to evolve, so too will the applications and innovations surrounding heavy duty grating, ensuring its place in the future of power generation.

The future of heavy duty grating in power generation plants looks promising, with ongoing research and development aimed at enhancing its properties. As the industry moves towards greener energy solutions, the role of innovative materials and manufacturing processes will become even more significant. Staying abreast of these developments will be essential for facility managers and engineers alike.

In summary, heavy duty grating for power generation plants is more than just a structural element; it is a vital component that supports the entire operation. From safety to efficiency, its impact is felt throughout the facility, making it an indispensable part of modern power generation.