Heavy duty grating installation in industrial yards is a critical process that ensures the safety and efficiency of operations. Industrial yards often require robust flooring solutions that can withstand heavy loads, harsh chemicals, and extreme weather conditions. This article delves into the various aspects of heavy duty grating installation, including materials, methods, and best practices.

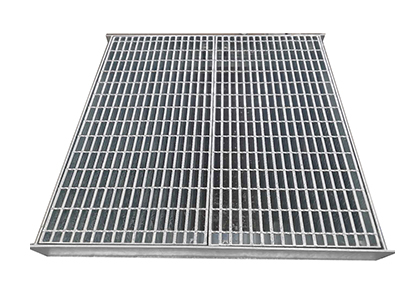

The first step in heavy duty grating installation in industrial yards is selecting the appropriate type of grating. Common materials include steel, aluminum, and fiberglass, each offering unique advantages. Steel grating is particularly popular due to its strength and durability, making it ideal for environments with heavy machinery and foot traffic.

Once the right material is chosen, the next step involves measuring the area where the grating will be installed. Accurate measurements are essential to ensure a perfect fit and to minimize waste. This process often includes assessing the load requirements and the potential for environmental factors that could affect the grating over time.

After measurements are taken, the installation process can begin. This typically involves preparing the sub-base to create a stable foundation for the grating. The sub-base must be level and compact to support the weight of the grating and any loads it will bear. Proper preparation is crucial to prevent future issues such as warping or settling.

Poste, the heavy duty grating panels are cut to size if necessary. Cutting should be done with precision tools to ensure clean edges and a perfect fit. This step may require specialized equipment, especially for thicker materials. Safety precautions should be taken to protect workers during this process, including the use of personal protective equipment.

Once the panels are cut, they can be laid down in the designated area. It is important to follow the manufacturer’s guidelines for spacing and alignment to ensure structural integrity. Panels should be placed in a manner that allows for proper drainage and prevents water accumulation, which can lead to corrosion and damage.

The next phase of heavy duty grating installation involves securing the panels in place. This can be done using various methods, including welding, bolting, or using clips. The choice of securing method depends on the type of grating and the specific requirements of the installation site. Proper fastening is essential to ensure the grating remains stable under load.

After the grating is secured, it is crucial to conduct a thorough inspection. This includes checking for any gaps, misalignments, or loose fittings. Any issues identified during the inspection should be addressed immediately to prevent safety hazards. A well-installed grating system can significantly enhance the safety of an industrial yard.

In addition to installation, maintenance is a vital aspect of heavy duty grating systems. Regular inspections and cleaning can prolong the lifespan of the grating and ensure it continues to perform effectively. Maintenance routines should include checking for signs of wear, corrosion, or damage, and addressing these issues promptly.

Another important consideration in heavy duty grating installation in industrial yards is compliance with safety regulations. Many industries are subject to strict safety standards that dictate the type of materials and installation methods that must be used. Understanding these regulations is crucial to avoid legal issues and ensure worker safety.

The environmental impact of heavy duty grating installation should also be taken into account. Choosing sustainable materials and practices can minimize the ecological footprint of the installation process. Many manufacturers now offer eco-friendly options that do not compromise on quality or performance.

Moreover, the aesthetic aspect of heavy duty grating cannot be overlooked. While functionality is paramount, the appearance of industrial yards can also affect the overall image of a company. Selecting grating that complements the surrounding environment can enhance the visual appeal of an industrial site.

Training workers on the proper installation techniques and safety protocols is essential for the success of any heavy duty grating project. Providing comprehensive training ensures that all personnel are aware of the potential risks and the best practices to mitigate them. This investment in training can lead to a more efficient and safer work environment.

In conclusion, heavy duty grating installation in industrial yards is a multifaceted process that requires careful planning and execution. From material selection to installation and maintenance, each step plays a crucial role in the overall effectiveness of the grating system. By following best practices and adhering to safety regulations, companies can ensure their industrial yards remain safe and functional for years to come.

As industries evolve, so do the technologies and materials used in heavy duty grating installation. Keeping up with the latest advancements can provide companies with better options that improve safety, efficiency, and sustainability. Staying informed about new products and methods can give businesses a competitive edge in the market.

Furthermore, collaboration with experienced contractors can enhance the quality of heavy duty grating installation projects. Engaging professionals who specialize in this field can ensure that installations are completed to the highest standards. Their expertise can also help in troubleshooting any challenges that arise during the installation process.

The future of heavy duty grating installation in industrial yards looks promising, with innovations in materials and installation techniques continually emerging. Companies that embrace these advancements will not only improve their operational efficiency but also contribute to a safer working environment for their employees.

In summary, heavy duty grating installation in industrial yards is a vital component of industrial infrastructure. By understanding the intricacies involved in the process, companies can make informed decisions that enhance safety, durability, and overall performance. Proper installation and maintenance of heavy duty grating systems are essential for long-term success in any industrial setting.