When faced with the task of choosing the right steel grating, it is essential to be well – informed. XINXING GRATING, as an international leading manufacturer in the steel grating industry, has extensive experience and knowledge that can guide you through this process.

Firstly, load capacity is a crucial factor when determining how to choose the right steel grating. Different types of steel grating from XINXING GRATING are engineered to support varying load capacities. Our company, with its advanced R&D capabilities and state – ของ – the – art production facilities, including 4 flat steel production lines and 17 สายการผลิตการเชื่อมด้วยแรงดันขั้นสูง, produces steel gratings that can meet diverse load requirements. It is vital to match the load – bearing needs of your specific project with the appropriate steel grating type to ensure safety and durability.

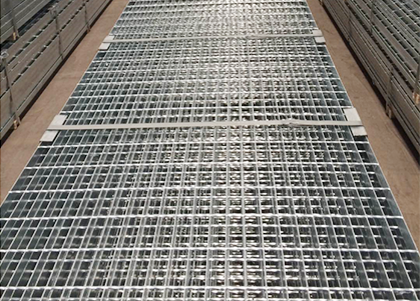

The environment in which the steel grating will be installed is another significant consideration in choosing the right steel grating. For applications where the steel grating might be exposed to corrosive elements such as salt water or chemicals, XINXING GRATING offers galvanized or stainless – steel gratings. These options provide excellent resistance to corrosion, thanks to our advanced hot – dip galvanizing production lines. In contrast, for indoor applications where the risk of corrosion is minimal, a standard steel grating from our wide range of products might be sufficient. Our ability to produce flat steel within the range of 19*3mm – 150*10mm and grating with spacing from 12.5mm – 100mm allows us to customize the product based on the environmental demands.

Size and shape also play a key role in choosing the right steel grating. The spacing between the bearing bars and cross bars, along with the overall dimensions of the grating, have a direct impact on its performance. XINXING GRATING’s comprehensive production process, which integrates equipment R&D, flat steel production, การประมวลผลตะแกรง, hot – dip galvanizing, and railway logistics, enables us to manufacture steel gratings with precise size and shape specifications to meet the specific requirements of different applications.

The method of installation is an often – overlooked but important factor when it comes to choosing the right steel grating. Different types of steel grating from XINXING GRATING may require different installation techniques. Our technical team can provide detailed guidance based on the type of grating you choose, ensuring a smooth and proper installation process.

Long – term maintenance is another aspect that cannot be ignored when choosing the right steel grating. Some types of steel gratings may demand more frequent maintenance than others. XINXING GRATING’s products are designed with maintenance in mind. Our high – quality steel gratings are built to last, but proper maintenance is still necessary to extend their lifespan. With our customer – first approach, we can help you choose a type of steel grating that fits well within your maintenance schedule and capabilities.

แผ่นปิดร่องลึก – specific requirements or standards are also vital considerations in choosing the right steel grating. For instance, in the food processing industry, there are specific regulations regarding the type of grating that can be used. XINXING GRATING, as one of the major drafters units of the steel gratings industry standard YB/T4001.1 – 2019, ensures that our products comply with relevant industry standards. Our steel grating products are widely used in various fields such as petrochemicals and municipal engineering, with a leading domestic market share and significant international exports.

In conclusion, choosing the right steel grating is a complex process that requires careful consideration of multiple factors. XINXING GRATING’s wide range of high – quality products, combined with our expertise and commitment to customer satisfaction, can assist you in making the best choice for your specific application. By thoroughly evaluating load capacity, environment, size and shape, installation method, maintenance requirements, and industry – specific standards, you can ensure that you select the right steel grating that will serve your needs effectively.