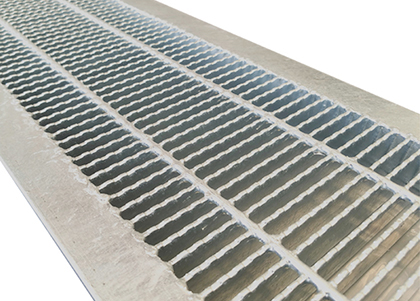

Narrow pitch grating for electrical enclosures is an essential component in modern electrical systems. It provides a robust solution for protecting sensitive electrical equipment from environmental factors, ensuring longevity and reliability. The design of narrow pitch grating allows for optimal airflow while preventing larger debris from entering the enclosure, making it an ideal choice for various applications.

One of the primary benefits of narrow pitch grating for electrical enclosures is its ability to enhance ventilation. Proper airflow is crucial in preventing overheating of electrical components, which can lead to failures and costly downtime. The narrow pitch design ensures that air can circulate freely while keeping out dust and other contaminants.

In addition to ventilation, narrow pitch grating also plays a significant role in safety. By preventing unauthorized access to electrical components, it helps to mitigate the risk of electrical shocks and accidents. This is particularly important in industrial settings where high voltages are present and safety regulations must be strictly adhered to.

The materials used in narrow pitch grating for electrical enclosures are typically corrosion-resistant, such as stainless steel or aluminum. This ensures that the grating can withstand harsh environmental conditions, including exposure to moisture and chemicals. The durability of these materials contributes to the overall lifespan of the electrical enclosure, reducing the need for frequent replacements.

Installation of narrow pitch grating is relatively straightforward, making it a popular choice among electrical engineers and contractors. The grating can be easily cut to size and fitted into existing enclosures, providing a customizable solution for various projects. This adaptability is one of the reasons why narrow pitch grating is favored in both new constructions and retrofitting applications.

Moreover, narrow pitch grating can be designed to meet specific load requirements. This is particularly important in applications where heavy equipment may be placed on or near the enclosure. By selecting the appropriate grating thickness and material, engineers can ensure that the enclosure can support the necessary weight without compromising safety or functionality.

Another significant advantage of narrow pitch grating for electrical enclosures is its aesthetic appeal. Many manufacturers offer a variety of finishes and colors, allowing for integration into different architectural designs. This is especially beneficial in commercial settings where appearance is just as important as functionality.

The versatility of narrow pitch grating extends to its applications across various industries. From telecommunications to power generation, this grating is utilized in environments where electrical safety and equipment protection are paramount. Its ability to adapt to different requirements makes it a go-to solution for many engineers.

When selecting narrow pitch grating for electrical enclosures, it is essential to consider factors such as spacing, load capacity, and material. These elements will determine the effectiveness of the grating in protecting the electrical components while ensuring adequate ventilation. Consulting with a specialist can help in making the right choice for specific applications.

Regular maintenance of narrow pitch grating is also crucial to ensure its effectiveness. Periodic inspections can help identify any signs of wear or damage, allowing for timely repairs or replacements. This proactive approach can significantly extend the life of the electrical enclosure and its components.

In conclusion, narrow pitch grating for electrical enclosures is a vital element in modern electrical infrastructure. Its combination of safety, durability, and aesthetic appeal makes it an ideal choice for a wide range of applications. By understanding the benefits and considerations associated with this grating, engineers can make informed decisions that enhance the performance and longevity of electrical systems.

As technology continues to advance, the design and manufacturing processes of narrow pitch grating are also evolving. Innovations such as improved materials and fabrication techniques are leading to even more efficient and effective solutions for electrical enclosures. Staying updated with these advancements can provide a competitive edge in the industry.

The environmental impact of narrow pitch grating is another important consideration. Many manufacturers are now focusing on sustainable practices, using recyclable materials and reducing waste during production. This shift not only benefits the environment but also appeals to consumers who are increasingly conscious of sustainability.

In terms of regulatory compliance, narrow pitch grating must meet specific standards set by organizations such as the National Electrical Manufacturers Association (NEMA). Understanding these requirements is essential for ensuring that the grating used in electrical enclosures adheres to safety and performance guidelines.

The economic aspect of narrow pitch grating should not be overlooked. While initial costs may vary depending on material and design, the long-term savings associated with reduced maintenance and extended lifespan can make it a cost-effective solution. Businesses should weigh these factors when budgeting for electrical enclosure projects.

Furthermore, the integration of narrow pitch grating with other protective measures, such as seals and gaskets, can enhance the overall effectiveness of electrical enclosures. This multi-layered approach ensures that enclosures are not only ventilated but also protected from moisture and dust ingress.

Training and education on the installation and maintenance of narrow pitch grating are crucial for ensuring optimal performance. Offering workshops and resources for engineers and contractors can improve the quality of installations and help prevent common issues associated with improper fitting or neglect.

The future of narrow pitch grating for electrical enclosures looks promising, with ongoing research and development aimed at improving functionality and efficiency. As industries continue to evolve, so too will the solutions available for protecting electrical systems, making it an exciting area for innovation.

In summary, narrow pitch grating is more than just a protective barrier; it is a critical component that enhances the safety and functionality of electrical enclosures. By investing in high-quality grating and understanding its benefits, businesses can ensure the reliability of their electrical systems for years to come.

As we move forward, the role of narrow pitch grating in electrical enclosures will continue to be essential. Its ability to provide safety, efficiency, and aesthetic value will keep it at the forefront of electrical engineering solutions.