Narrow pitch grating for small parts sorting is an innovative solution designed to enhance the efficiency and accuracy of sorting small components in various industries. This technology addresses the increasing demand for precision in manufacturing processes, where even the slightest error can lead to significant financial losses. By utilizing narrow pitch gratings, businesses can streamline their sorting operations, ensuring that small parts are categorized correctly and efficiently.

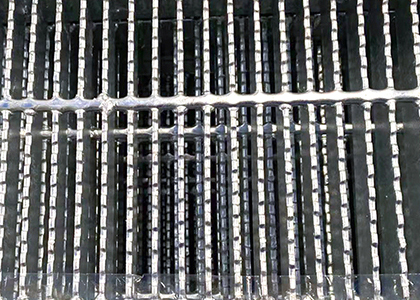

The fundamental principle behind narrow pitch gratings lies in their design. These gratings feature closely spaced grooves that allow for the separation of small parts based on size, shape, and material properties. This precision is crucial in industries such as electronics, automotive, and medical device manufacturing, where components can be minuscule yet vital to the overall function of the final product. Understanding how these gratings work can help businesses optimize their production lines.

One of the key advantages of using narrow pitch grating for small parts sorting is the increase in throughput. Traditional sorting methods can be slow and prone to errors, especially when dealing with tiny components. بهرحال, narrow pitch gratings can handle large volumes of parts simultaneously, reducing the time required for sorting and allowing for more efficient use of resources. This boost in productivity can significantly impact a company’s bottom line.

In addition to improving throughput, narrow pitch gratings also enhance the accuracy of sorting. The precise alignment of small parts within the grooves of the grating ensures that each component is sorted correctly, minimizing the risk of misclassification. This level of accuracy is essential for industries that require strict adherence to quality standards, as even minor discrepancies can lead to product recalls and reputational damage.

The versatility of narrow pitch gratings makes them suitable for a wide range of applications. From sorting electronic components like resistors and capacitors to small mechanical parts such as screws and washers, these gratings can be customized to meet the specific needs of different industries. This adaptability is a significant benefit for manufacturers looking to implement a one-size-fits-all solution for their sorting challenges.

Another important aspect of narrow pitch grating technology is its integration with automation systems. As industries increasingly turn to automation to enhance efficiency, the compatibility of narrow pitch gratings with robotic sorting systems becomes a critical factor. These gratings can be seamlessly integrated into automated production lines, allowing for real-time sorting and minimizing human intervention, which can lead to errors.

The material composition of narrow pitch gratings also plays a vital role in their effectiveness. Typically made from durable materials such as stainless steel or high-grade plastics, these gratings are designed to withstand the rigors of industrial environments. The choice of material not only affects the longevity of the grating but also its performance in terms of friction and wear, which can impact the sorting process.

Maintenance of narrow pitch gratings is relatively straightforward, making them an attractive option for manufacturers. Regular cleaning and inspection can ensure that the gratings remain free from debris and contaminants, which could hinder their performance. Establishing a routine maintenance schedule can help companies maximize the lifespan of their sorting equipment and maintain optimal efficiency in their operations.

The cost-effectiveness of narrow pitch grating for small parts sorting cannot be overlooked. While the initial investment in such technology may seem significant, the long-term savings achieved through increased efficiency and reduced errors can quickly offset these costs. Companies that adopt this technology often find that they achieve a rapid return on investment, making it a financially sound choice.

نتيجي ۾, narrow pitch grating for small parts sorting represents a significant advancement in sorting technology. Its ability to enhance throughput, accuracy, and integration with automation systems makes it an indispensable tool for modern manufacturing. As industries continue to evolve and demand higher precision, the adoption of narrow pitch gratings will likely become increasingly prevalent, ensuring that businesses remain competitive in a fast-paced market.

The future of narrow pitch grating technology looks promising, with ongoing research and development aimed at improving its capabilities further. Innovations in materials science and engineering are expected to lead to even more efficient designs that can handle a wider variety of components. This continuous evolution will keep narrow pitch gratings at the forefront of sorting technology for years to come.

وڌيڪ, the environmental impact of narrow pitch grating for small parts sorting is worth mentioning. As industries strive to become more sustainable, the energy efficiency of sorting systems becomes a critical concern. Narrow pitch gratings, particularly when integrated with automated systems, can significantly reduce energy consumption during the sorting process, contributing to greener manufacturing practices.

Training staff to effectively use narrow pitch gratings is another important consideration. While the technology itself may be straightforward, ensuring that employees understand the best practices for sorting small parts can enhance the overall effectiveness of the system. Providing comprehensive training programs can help maximize the benefits of narrow pitch grating technology in any manufacturing environment.

The global market for narrow pitch grating technology is expanding, with increasing demand across various sectors. As more companies recognize the advantages of this sorting method, the competition among manufacturers of narrow pitch gratings is likely to intensify. This competition can lead to innovations that further enhance the performance and affordability of these systems, benefiting end-users in the long run.

خلا ۾, narrow pitch grating for small parts sorting is a vital component in modern manufacturing processes. Its ability to improve efficiency, accuracy, and integration with automation systems positions it as a key player in the future of sorting technology. As industries continue to evolve, the importance of adopting advanced sorting solutions like narrow pitch gratings will only grow, ensuring that businesses can meet the challenges of an increasingly competitive market.

For businesses considering the implementation of narrow pitch grating technology, it is essential to conduct a thorough assessment of their specific needs. This assessment should include an evaluation of the types of parts being sorted, the required throughput, and the integration with existing systems. By understanding these factors, companies can make informed decisions that align with their operational goals and budget constraints.

Ultimately, the choice to invest in narrow pitch grating for small parts sorting can lead to significant improvements in manufacturing efficiency. The ability to accurately and quickly sort small components can streamline production processes, reduce waste, and enhance overall product quality. As the manufacturing landscape continues to evolve, technologies like narrow pitch gratings will play a crucial role in shaping the future of the industry.