Steel grating is a type of grating made of steel grating. It is used for flooring, catwalks, AS1650, and various other applications. Steel grating is known for its high strength, durability, and load-bearing capabilities.

One of the most frequently asked questions about steel grating is its material. Steel grating is commonly made of carbon steel, 不锈钢, or aluminum. Each material has its own advantages and is chosen based on the specific requirements of the application.

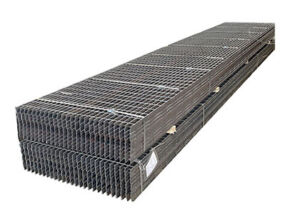

Another common question is about the types of steel grating available. The most common types include welded steel grating, 压锁钢格板, riveted steel grating, and swage-locked steel grating. Each type has its unique characteristics and is suitable for different environments and load requirements.

Many people also wonder about the installation of steel grating. The installation process involves laying the grating panels on the supporting structure and securing them with fasteners. It is important to ensure proper alignment and spacing during the installation to achieve the desired performance.

The question of load capacity often arises when it comes to steel grating. The load capacity of steel grating is determined by factors such as the size and spacing of the load bars, as well as the type of grating used. It is essential to consult load tables and engineering guidelines to select the appropriate grating for a specific application.

In terms of surface treatment, steel grating can be galvanized or coated with paint. Galvanized steel grating offers excellent corrosion resistance, making it suitable for outdoor and industrial environments. On the other hand, painted steel grating provides aesthetic appeal and additional protection against corrosion.

Safety is a significant concern for many users of steel grating. To ensure safety, it is essential to consider factors such as the slip resistance of the grating, the presence of serrated edges, and the load capacity. Additionally, proper maintenance and regular inspections are crucial for ensuring the safety and integrity of steel grating.

When it comes to purchasing steel grating, customers often inquire about the availability of custom designs and sizes. Many manufacturers offer custom fabrication services to meet specific project requirements. This includes the ability to customize the dimensions, materials, and surface treatments of the grating.

The topic of industry standards and certifications is also important in the context of steel grating. It is essential to ensure that the grating meets relevant industry standards and specifications to guarantee its quality and performance. Common certifications for steel grating include ASTM, NAAMM, and ANSI.

Maintenance and care are crucial aspects of prolonging the lifespan of steel grating. Regular cleaning to remove debris and contaminants, as well as inspections for signs of wear and corrosion, are essential for maintaining the integrity and performance of the grating. Proper maintenance can prevent safety hazards and extend the service life of the grating.

Steel grating is widely used in various industries, including manufacturing, construction, oil and gas, transportation, and infrastructure. Its versatility, strength, and durability make it a preferred choice for applications that require efficient drainage, ventilation, and load-bearing capabilities.

In conclusion, steel grating is a versatile and durable material that offers numerous benefits for a wide range of applications. By understanding the material options, types, installation process, load capacity, surface treatments, safety considerations, customization options, industry standards, and maintenance practices, users can make informed decisions regarding the use and procurement of steel grating.