In the complex landscape of noise control within industrial and commercial arenas, irin for acoustic enclosures has emerged as an indispensable element. Among the numerous global providers of steel grating, XINXING GRATING has firmly established itself as a leading figure, especially when it comes to meeting the specialized demands of acoustic enclosure applications.

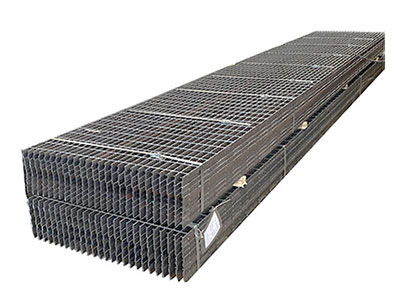

Xinxing ti nraja ni ipilẹ-ọna ọlọrọ ati lapẹẹrẹ. Ipilẹṣẹ lati awọn 2672 Ile-iṣẹ imọ-ẹrọ ti Ẹgbẹ Ọmọ-Ọmọ Ọmọ-Ọmọde Ninu 1971 ati lilọ gbangba lori paṣipaarọ ọja iṣura sheenzhen ninu 1997, it has evolved into the core enterprise of Xinxing International Group, ṣe abojuto nipasẹ ipinle – Awọn ohun ini ohun ini abojuto abojuto ati ilana ijọba ti Igbimọ Ipinle (SASAC). The company has become an international – yori r&D aṣese ti tẹ – welded irin, awọn eroja, ati ọpọlọpọ awọn afikọti Syeed. Niwon ṣafihan laini iṣelọpọ ẹrọ alaifọwọyi 1994 and commencing production, XINXING GRATING has continuously grown. It now boasts 4 alapin, irin gbóògì ila, 17 Ti ilọsiwaju – Awọn Ila-iṣẹ Alagbero, 3 gbona – Disvanlizing iṣelọpọ awọn ila, Irin grating pẹtẹẹsì wa o si wa ni iru “W” welded 1 Railing ati ina – irin awọn ẹya ara ẹrọ iṣelọpọ iṣelọpọ iṣelọpọ. Pẹlu agbara iṣelọpọ lododun ti 120,000 Tons ti irin-ajo irin ati awọn ẹya ẹrọ, ati agbara lati ṣe agbejade irin irin ajo lati 193mm si 15010mm pẹlu aye lati 12.5mm si 100mm, the company is well – equipped to meet diverse market needs.

Ni afikun, it holds independent intellectual property rights for the R&D ati apẹrẹ titẹ – awọn ẹrọ alurinrin, houses a nationally recognized enterprise technology R&D aarin, and has a post – dokita alagbeka alagbeka iṣẹ ṣiṣe. Bi ẹya afikun ti o pọ sii, O bo gbogbo awọn abala lati awọn ohun elo r&D to alapin irin gbóògì, grating processing, gbona – Dirvanlizing, ati awọn eekapa ọkọ oju irin. It is also one of the major drafters of the steel grating industry standard YB/T4001.1 – 2019.

Steel grating for acoustic enclosures provided by XINXING GRATING is crucial for effective noise control. In industrial and commercial settings, gẹgẹbi awọn ohun elo agbara, manufacturing facilities, and transportation infrastructure, noisy equipment and machinery are prevalent. The steel grating systems are engineered to enclose these noisy sources, creating a quieter and safer work environment. The robust construction of XINXING GRATING’s steel grating, achieved through its 17 Ti ilọsiwaju – Awọn Ila-iṣẹ Alagbero, ensures structural stability. This stability is essential as the acoustic enclosures need to withstand various forces, including vibrations from the machinery and potential impacts.

One of the key benefits of XINXING GRATING’s steel grating for acoustic enclosures is enhanced sound absorption. The design of the steel grating, combined with appropriate sound – absorbing materials (if used in conjunction), helps to reduce the transmission of noise. Fun apẹẹrẹ, in a large – scale power plant in [Location Name], the generators produce an extremely high level of noise. XINXING GRATING’s steel grating, installed in the acoustic enclosures around these generators, effectively dampened the sound waves. Ṣii – design structure of the grating, along with the supplementary sound – absorbing panels, reduced the noise level in the adjacent control room by a significant 20 decibels. This not only improved the working conditions for the operators but also ensured compliance with local noise – pollution regulations.

Proper ventilation and airflow are equally important in acoustic enclosures, and XINXING GRATING’s steel grating excels in this regard. Ninu awọn eto ile-iṣẹ, equipment generates heat during operation, and adequate ventilation is necessary to prevent overheating. In a manufacturing facility producing [Product Name], the machinery runs continuously and generates a substantial amount of heat. Ṣii – grid design of XINXING GRATING’s steel grating, installed in the acoustic enclosures, allowed air to circulate freely around the equipment. This maintained the optimal operating temperature of the machinery, preventing any heat – related malfunctions. Awọn 3 gbona – dip galvanizing production lines at XINXING GRATING enhanced the corrosion resistance of the steel grating, ensuring its long – term performance even in the humid environment of the manufacturing plant.

XINXING GRATING offers a wide range of customization options for steel grating used in acoustic enclosures. Given the diverse requirements of different industrial and commercial applications, the company can tailor the steel grating to fit specific needs. Fun apere, in a transportation infrastructure project involving a subway maintenance depot in [City Name], the acoustic enclosures needed to be highly durable and able to withstand heavy equipment movement. XINXING GRATING fabricated a custom – made steel grating with a higher load – ipa. The ability to produce flat steel in a wide range of sizes and with various spacing options enabled the creation of a grating that precisely met the unique demands of the depot. The grating not only provided effective noise control but also ensured the safety of the maintenance workers by offering a stable surface to walk on.

The installation of steel grating for acoustic enclosures requires careful planning, ati xinxing titari pese atilẹyin pipe. Awọn iṣẹ ile-iṣẹ, eyiti o wa lati inu ohun elo r&D si awọn eekapa, Rii daju pe ilana fifi sori ẹrọ ti ko ni sampless. Their team of experts can assess the specific requirements of each project, taking into account factors such as the type of equipment to be enclosed, the noise levels to be controlled, and the environmental conditions of the installation site. Wọn le lẹhinna ṣeduro iru iru mimu ti o dara julọ ti irin ati pese itọsọna lori ilana fifi sori ẹrọ., pẹlu yiyan ti awọn ẹya atilẹyin ti o yẹ ati awọn ọna iyara. This ensures the stability and effectiveness of the grating system, giving customers confidence in their noise – control solutions.

Regular inspection and maintenance of the steel grating in acoustic enclosures are essential, ati fifi sori ẹrọ xinxing tẹnumọ abala yii. Ile-iṣẹ naa lẹhin – Iṣẹ tita pẹlu awọn eto ayewo deede lati ṣe idanimọ eyikeyi awọn ami ti wọ tabi bibajẹ. In industrial and commercial environments, where the steel grating is exposed to harsh conditions, O ṣe pataki lati rii awọn ọran ati adirẹsi adirẹsi ni kutukutu. Nipa ṣiṣe bẹ, Xinxing n ṣe iranlọwọ idiwọ awọn fifọ airotẹlẹ, Awọn atunṣe idiyele, ati awọn ewu ailewu ti o ni agbara. Ẹgbẹ wọn le yarayara ropo awọn ẹya ti o bajẹ, ensuring that the steel grating for acoustic enclosures remains in optimal condition, continuing to provide effective noise control and a safe working environment.

Xinxing irin awọn ọja, especially those designed for acoustic enclosures, Ni jakejado – reaching impact. Wọn ti lo niya ni ọpọlọpọ awọn aaye bii awọn ile kekere ati imọ-ẹrọ ilu, but their application in noise – control solutions is of particular significance. Ni ọja ile, Xinxing Nlagina ni ipo adari ninu irin-iṣẹ igbega irin. Sunmọ nkan 30% ti awọn ọja rẹ ni okeere si diẹ sii ju 30 Awọn orilẹ-ede ati awọn agbegbe ni ayika agbaye, ṣiṣe rẹ ni olupese ilu okeere ti ile ni agbegbe yii. Ifarabalẹ ti ile-iṣẹ si tetet ti "didara akọkọ, customer first” is evident in every steel grating product it supplies for acoustic enclosures. Nipa gbidun si imọran iye ti win – win ifowosowopo ati ṣajọ – ẹda ati pinpin, XINXING GRATING is dedicated to growing together with industrial and commercial customers. O ni ero lati pese wọn pẹlu ti o dara julọ – ninu – class steel grating solutions for acoustic enclosures that enhance noise control, improve working conditions, and contribute to the overall efficiency of industrial and commercial operations.

Ni paripari, irin for acoustic enclosures provided by XINXING GRATING is an invaluable asset for noise control in industrial and commercial settings. Its sound – absorbing properties, structural stability, ventilation capabilities, Awọn aṣayan Isọdi, and the support provided during installation and maintenance make it the ideal choice for acoustic enclosure applications. It plays a crucial role in creating a quieter and safer work environment, enabling industries to operate more efficiently while minimizing the impact of noise pollution.