Irin fun ororo fun epo ati gaasi daradara awọn aaye: XINXING GRATING’s Indispensable Solution

In the complex and challenging realm of oil and gas well sites, irin emerges as a linchpin for guaranteeing safety, mu ṣiṣe ṣiṣe, ati irọrun awọn iṣẹ iṣeeṣe. Xinxing Spating, Ile-iṣẹ pẹlu ororo nla ati ipinlẹ – ti – awọn – Aṣoju iṣelọpọ, ti fi ara ara rẹ mulẹ funrararẹ bi olupese ti o wa ti giga – Didara irin awọn ọna asopọ ti didara ti a ṣe deede si awọn ibeere eto ṣiṣe ti epo ati gaasi daradara.

Company Background and Strengths

XINXING GRATING traces its origins back to 1971, Nigbati o ba ni ipilẹ bi awọn 2672 Ile-iṣẹ imọ-ẹrọ ti ọmọ ogun ti awọn eniyan. Lati igbanna, it has undergone remarkable growth and transformation. Ninu 1997, it was listed on the Shenzhen Stock Exchange and has since become the core enterprise of Xinxing International Group, ṣe abojuto nipasẹ ipinle – Awọn ohun ini ohun ini abojuto abojuto ati ilana ijọba ti Igbimọ Ipinle (SASAC). This position has enabled the company to continuously drive innovation in the steel grating industry.

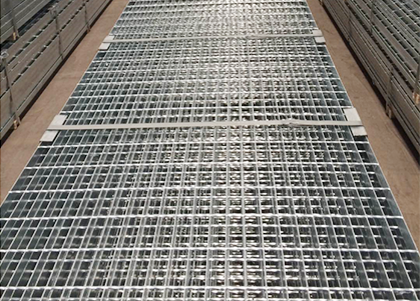

Ile-iṣẹ naa ṣafihan laini iṣelọpọ irin grating ni kikun ti Japan ni 1994 and has since expanded its manufacturing capabilities significantly. Lọwọlọwọ, it boasts an impressive setup with 4 alapin, irin gbóògì ila, 17 Ti ilọsiwaju – Awọn Ila-iṣẹ Alagbero, Irin grating pẹtẹẹsì wa o si wa ni iru “W” welded 3 gbona – Disvanlizing iṣelọpọ awọn ila. Complemented by 1 afowodimu ati ina, irin igbekale awọn ẹya ara isejade onifioroweoro, XINXING GRATING has an annual production capacity of 120,000 Tons ti irin-ajo irin ati awọn ẹya ẹrọ. This vast production capacity allows it to meet the diverse needs of oil and gas well sites, whether they are large – scale operations or smaller, more specialized setups.

XINXING GRATING also holds independent intellectual property rights for the R&D ati oniru ti titẹ alurinmorin ero. Pẹlu imọ-ẹrọ ile-iṣẹ ti ara ilu&D aarin ati ifiweranṣẹ kan – dokita alagbeka alagbeka iṣẹ ṣiṣe, the company is at the forefront of technological advancements. It is not only an integrated supplier of steel grating, bo gbogbo abala lati awọn ohun elo r&D to alapin irin gbóògì, grating processing, gbona – Dirvanlizing, and railway logistics but also one of the major drafters of the steel gratings industry standard YB/T4001.1 – 2019. This expertise and influence in the industry are a testament to the high – quality and reliable products it offers for oil and gas well sites.

Applications of Steel Grating at Oil and Gas Well Sites

Secure Walkways and Platforms

Steel grating for oil and gas well sites is primarily used for constructing secure walkways and platforms. These are essential for workers to safely traverse the well site, access vital equipment, and carry out maintenance and operational tasks. XINXING GRATING’s products offer an outstanding strength – iwọn lati 993mm si – weight ratio. This means that the steel grating can support heavy loads, such as workers, Awọn irin, and small equipment, while remaining lightweight enough to be easily installed and maneuvered. Fun apẹẹrẹ, in large oil refineries or gas processing plants, where there is a constant flow of workers and the need to move equipment around, XINXING’s steel grating provides a stable and reliable surface.

Ṣii – grid design of XINXING’s steel grating is a game – changer in terms of drainage. Oil and gas well sites are often exposed to various weather conditions, pẹlu ojo, yinyin, and even oil or chemical spills. The open design allows for the efficient drainage of these liquids. Rainwater can quickly flow through the gaps in the grating, preventing the formation of slippery surfaces that could lead to accidents. Similarly, in the event of oil or chemical leaks, the grating enables the safe and rapid removal of these potentially hazardous substances, reducing the risk of environmental contamination and ensuring a safer working environment.

Stair Treads, Ladder Rungs, and Catwalks

Another crucial application of steel grating for oil and gas well sites is in the creation of stair treads, ladder rungs, and catwalks. These components are necessary for providing safe and stable access to elevated areas, such as drilling platforms, storage tanks, and processing equipment. XINXING GRATING’s ability to customize steel grating according to specific dimensional and load requirements is highly beneficial here.

Fun apere, in a drilling rig where workers need to access different levels multiple times a day, the stair treads and ladder rungs made from XINXING’s steel grating can be designed to provide maximum grip and stability. Awọn ti kii ṣe – slip surface of the grating ensures that workers can safely ascend and descend, even in challenging conditions. Catwalks, which are often used to connect different parts of the well site or to access equipment at height, can also be customized to fit the layout of the site precisely. This customization not only enhances the safety of the workers but also improves the overall productivity of the well site, as workers can move around more efficiently.

Durability and Resistance to Harsh Conditions

Oil and gas well sites are known for their harsh conditions, including extreme temperatures, heavy loads, and exposure to corrosive substances. XINXING GRATING’s steel grating is engineered to withstand these challenges with ease. The top – grade steel materials used in production, combined with the advanced manufacturing processes, result in a product that is highly durable.

Awọn 17 Ti ilọsiwaju – welding production lines at XINXING GRATING ensure that the steel grating has a robust structure, capable of withstanding the continuous movement of heavy equipment and the weight of workers. Awọn 3 gbona – dip galvanizing production lines add an extra layer of protection. The galvanized finish makes the steel grating highly resistant to corrosion, even when exposed to harsh chemicals, saltwater (in offshore oil and gas operations), and other corrosive substances commonly found at well sites. This corrosion resistance ensures that the steel grating for oil and gas well sites maintains its structural integrity and performance over an extended period, reducing the need for frequent replacements and minimizing downtime.

Market Reach and Customer – Centric Approach

Xi Di irin products have a wide – ranging application scope and are highly regarded in various industries, with petrochemicals being one of the key sectors. In the context of oil and gas well sites, their products have gained significant recognition. The domestic market share of XINXING’s products is in a leading position within the industry, ati to 30% of their products are exported to more than 30 Awọn orilẹ-ede ati awọn agbegbe ni ayika agbaye. This global footprint is a testament to the quality and reliability of their steel grating for oil and gas well sites.

XINXING GRATING adheres firmly to the tenet of “quality first, onibara akọkọ". The company is dedicated to providing oil and gas well site operators with top – Awọn ọja didara ati awọn iṣẹ itelorun. By choosing XINXING GRATING’s steel grating for oil and gas well sites, operators can be confident that they are investing in a product that combines safety, agbara, Awọn aṣayan Isọdi, ati fifa daradara. The company’s commitment to win – win ifowosowopo ati ṣajọ – creation and sharing means that it works closely with its customers to understand their specific needs and provide tailored solutions. This approach ensures long – term partnerships and mutual growth, making XINXING GRATING the ideal choice for oil and gas well site operators looking to optimize their operations and create a safe and efficient working environment.

Ni paripari, XINXING GRATING’s steel grating for oil and gas well sites is an outstanding solution that meets the critical requirements of the oil and gas industry. Its safety features, agbara, wide range of applications, Awọn aṣayan Isọdi, and global reputation make it the go – to choice for well site operators aiming to enhance the safety and productivity of their operations.