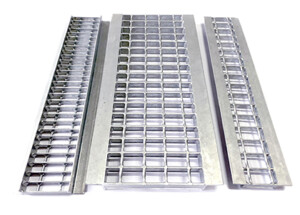

Steel grating quality assurance is essential for ensuring the safety and durability of industrial flooring systems. Quality assurance measures include material inspection, welding quality control, and load testing.

Material inspection is the first step in ensuring steel grating quality. This involves checking the raw materials for compliance with industry standards and specifications. It includes assessing the chemical composition, mechanical properties, and surface condition of the steel.

Welding quality control is another critical aspect of steel grating quality assurance. Proper welding ensures the structural integrity of the grating. It involves inspecting the welding process, ensuring proper penetration, and evaluating the quality of the welds.

Load testing is conducted to verify the structural strength and load-bearing capacity of the steel grating. This involves subjecting the grating to various loads to assess its performance under different conditions. It helps ensure that the grating can withstand the intended loads and usage.

Quality assurance also extends to the surface treatment of steel grating. Proper surface treatment, such as hot-dip galvanizing or painting, is essential for corrosion resistance and longevity. It involves inspecting the coating thickness, adhesion, and overall quality of the surface treatment.

Regular inspections and maintenance are essential for ongoing quality assurance. Periodic inspections help identify any issues or defects early, allowing for timely repairs and maintenance. This helps prolong the service life of the steel grating and ensures continued safety and performance.

In addition to inspections, proper installation is crucial for steel grating quality assurance. Following the manufacturer’s guidelines and best practices for installation helps ensure the structural integrity and performance of the grating. It also minimizes the risk of installation-related issues that could affect quality.

Training and certification of personnel involved in the manufacturing, installation, and maintenance of steel grating are also important for quality assurance. Properly trained and certified personnel are more likely to adhere to quality standards and best practices, contributing to overall quality assurance.

Steel grating quality assurance is vital for various industries, including oil and gas, manufacturing, transportation, and construction. It helps ensure the safety of workers, the durability of flooring systems, and the overall integrity of industrial infrastructure.

In conclusion, steel grating quality assurance encompasses various measures to ensure the safety, durability, and performance of industrial flooring systems. From material inspection to load testing, each step plays a crucial role in maintaining quality standards and compliance with industry requirements.