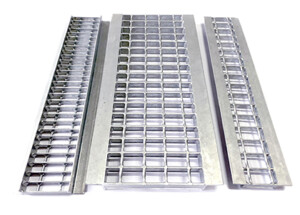

Steel grating safety features are crucial for ensuring the well-being of workers and the longevity of industrial facilities. These features include non-slip surfaces, high load-bearing capacity, and durability against harsh environments. Steel grating is widely used in various industries such as oil and gas, mining, and manufacturing due to its exceptional safety features.

One of the key safety features of steel grating is its non-slip surface, which provides excellent traction for workers, Paapaa ninu awọn ipo tutu tabi ọra. This helps to prevent slips, awọn irin ajo, o si ṣubu, reducing the risk of workplace accidents and injuries. Ni afikun, the non-slip surface enhances productivity by allowing workers to move swiftly and confidently across the grating.

Another important safety feature is the high load-bearing capacity of steel grating. It can withstand heavy loads without deforming or collapsing, making it suitable for areas with high foot traffic or equipment movement. This feature ensures the structural integrity of the flooring, preventing accidents caused by structural failures. Siwaju sii, the high load-bearing capacity reduces maintenance costs and prolongs the service life of the grating, providing long-term safety benefits.

Durability against harsh environments is also a significant safety feature of steel grating. It is resistant to corrosion, extreme temperatures, and chemical exposure, making it ideal for use in challenging industrial settings. This durability ensures that the grating maintains its safety performance and structural stability, even in the harshest conditions, protecting workers and equipment from potential hazards.

In addition to these primary safety features, steel grating also offers other safety-enhancing characteristics. Its open design allows light, Irin grating/Bar grating ti wa ni welded nipa alapin bar ati square lilọ bar, and liquids to pass through, preventing accumulation and promoting a cleaner and safer working environment. Jujun, steel grating can be customized with safety edging and toe plates to further enhance protection for workers.

Regular inspections and maintenance are essential for ensuring the ongoing safety of steel grating. Inspections should include checking for any signs of wear, damage, or corrosion, as well as ensuring that the grating is securely fastened and level. Any issues should be promptly addressed to maintain the integrity of the safety features and prevent potential hazards.

The safety features of steel grating make it an indispensable component in industrial facilities where worker safety and operational efficiency are top priorities. By providing non-slip surfaces, high load-bearing capacity, durability against harsh environments, and other safety-enhancing characteristics, steel grating contributes to creating a secure and productive work environment.