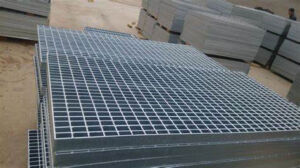

Steel grating and aluminum grating are two common materials used in industrial and commercial applications. Both have their own unique properties and benefits, making them suitable for different use cases.

Steel grating is known for its strength and durability, making it an ideal choice for heavy-duty applications such as industrial flooring, catwalks, and stair treads. It is also resistant to impact and heavy loads, making it a popular choice in areas with high traffic and heavy machinery.

On the other hand, aluminum grating is lightweight and corrosion-resistant, making it a popular choice for outdoor applications and areas where moisture and corrosion are a concern. It is also easy to install and requires minimal maintenance, making it a cost-effective option in the long run.

When comparing steel grating vs. aluminum grating, it’s important to consider the specific requirements of the application. Steel grating is ideal for high-traffic areas and heavy loads, while aluminum grating is better suited for outdoor and corrosion-prone environments.

In terms of cost, steel grating is generally more affordable upfront, but it may require more maintenance and upkeep compared to aluminum grating. However, the durability and strength of steel grating may outweigh the initial cost for certain applications.

Another factor to consider when choosing between steel grating and aluminum grating is the installation process. Steel grating is heavier and may require specialized equipment and expertise for installation, while aluminum grating is lightweight and can be easily installed by a smaller team.

In terms of aesthetics, both steel grating and aluminum grating offer a sleek and modern look, making them suitable for various architectural and design applications. Both materials are available in a range of finishes and styles to complement different design preferences.

When it comes to sustainability, aluminum grating is often considered the more eco-friendly option due to its lightweight nature and recyclability. However, steel grating can also be recycled and repurposed, making it a sustainable choice for certain projects.

In conclusion, the choice between steel grating and aluminum grating depends on the specific requirements of the project, including load capacity, durability, maintenance, cost, and environmental considerations. Both materials offer unique benefits and can be suitable for different applications.

When comparing steel grating vs. aluminum grating, it’s important to weigh the pros and cons of each material to make an informed decision that aligns with the project’s needs and long-term goals.