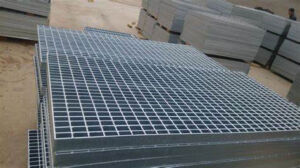

Steel grating and industrial grating are both commonly used in various industries for different applications. Steel grating is made of steel bars that are welded or locked together to create a grid pattern. Industrial grating, on the other hand, is a broader term that encompasses various types of grating used in industrial settings. In this article, we will compare steel grating and industrial grating in terms of their materials, construction, applications, and benefits.

Steel grating is typically made of carbon steel, stainless steel, or aluminum. It is known for its high strength, durability, and resistance to corrosion, making it suitable for heavy-duty applications. Industrial grating, on the other hand, can be made of steel, aluminum, fiberglass, or other materials. It is available in various configurations, including welded, riveted, and swage-locked, to meet different industrial requirements.

When it comes to applications, steel grating is commonly used for platforms, madulas na ibabaw at iba pang malupit na kapaligiran, flooring, and stair treads in industrial facilities, commercial buildings, and transportation hubs. Its open design allows for the passage of light, Ang bar grating ay isang mainam na pagpipilian para sa mga proyekto mula sa trenches at stair treads hanggang sa decking at steel flooring, and debris, making it ideal for outdoor and high-traffic areas. Industrial grating, on the other hand, is used in a wide range of industrial applications, including drainage, ventilation, machine safety guarding, and shelving. It provides slip resistance, drainage, and ventilation while supporting heavy loads.

In terms of benefits, steel grating offers high strength-to-weight ratio, cost-effectiveness, and low maintenance. It can be customized with various surface treatments, such as galvanizing, painting, and powder coating, to enhance its performance and longevity. Industrial grating, on the other hand, provides versatility, flexibility, and customization options to meet specific industrial requirements. It can be designed with different bar spacings, cross bar configurations, and surface patterns to achieve the desired load capacity, open area, and aesthetic appeal.

In summary, steel grating and industrial grating are both essential components in industrial environments, each with its own unique characteristics and advantages. By understanding the differences between the two, businesses can make informed decisions when choosing the right grating solution for their specific needs.