Steel grating and perforated metal grating are both popular choices for industrial applications. Steel grating is made of steel bars or plates, while perforated metal grating is made of metal sheets with holes punched into them. Both types of grating offer unique benefits and are suitable for different environments and uses.

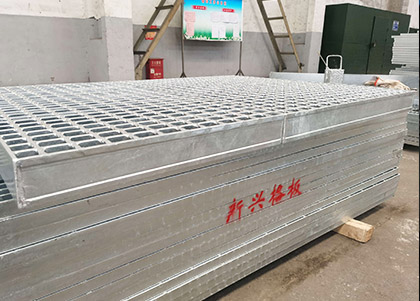

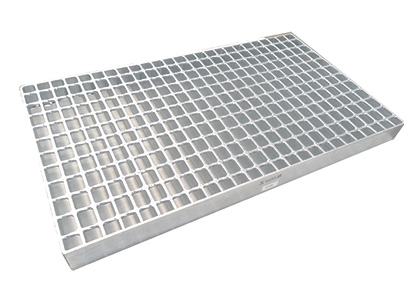

Steel grating is known for its high strength and durability, making it ideal for heavy-duty applications such as industrial flooring, catwalks, and stair treads. The open design allows for easy drainage and ventilation, while the sturdy construction can withstand heavy loads and harsh conditions. Perforated metal grating, ٻي پاسي, is lightweight and offers good visibility and airflow. It is often used in architectural and decorative applications, as well as for sunshades, باهه لڳائڻ, and infill panels.

When comparing steel grating vs perforated metal grating, it’s important to consider the specific requirements of the project. Steel grating is more suitable for heavy-duty industrial applications where strength and durability are paramount. It is also a cost-effective option for long-term use. Perforated metal grating, ٻي پاسي, is more versatile and can be used in a variety of architectural and decorative applications. It offers good visibility, airflow, and aesthetic appeal, making it a popular choice for projects where design and aesthetics are important.

In terms of installation and maintenance, steel grating and perforated metal grating have different requirements. Steel grating is heavier and may require professional installation, especially for large-scale projects. It also needs regular maintenance to prevent corrosion and ensure safety. Perforated metal grating, being lightweight and easy to handle, is easier to install and requires minimal maintenance. This makes it a convenient option for projects with budget and time constraints.

When it comes to safety and security, both steel grating and perforated metal grating offer reliable performance. Steel grating provides a stable and secure walking surface, making it suitable for industrial and commercial environments where safety is a priority. It also offers good slip resistance and can withstand heavy loads, making it a safe choice for high-traffic areas. Perforated metal grating, while not as strong as steel grating, still offers good traction and stability. It is often used in areas where visibility and airflow are important, such as stair treads, slippery مٿاڇري ۽ ٻين سخت ماحول, and walkways.

خلا ۾, the choice between steel grating and perforated metal grating depends on the specific requirements of the project. Steel grating is ideal for heavy-duty industrial applications that require strength, استحڪام, and long-term cost-effectiveness. It is suitable for environments with heavy loads, harsh conditions, and high safety standards. Perforated metal grating, ٻي پاسي, is more versatile and offers good visibility, airflow, and aesthetic appeal. It is often used in architectural and decorative applications, as well as for projects with budget and time constraints.