Steel grating and plank grating are two common types of grating used in industrial and commercial applications. Both have their own unique characteristics and advantages, making them suitable for different environments and purposes.

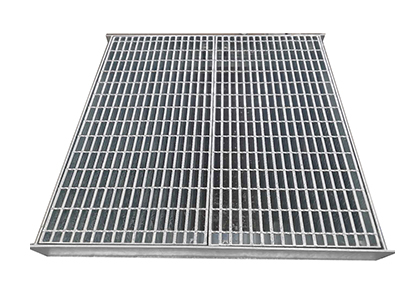

Steel grating is made of steel bars that are welded together to form a grid pattern. It is known for its high strength, durability, and load-bearing capacity. Steel grating is often used in heavy-duty applications such as industrial flooring, catwalks, and stair treads.

On the other hand, plank grating is constructed from a series of parallel metal bars that are joined together with perpendicular bars. It offers good ventilation, light transmission, and slip resistance, making it ideal for applications where drainage and safety are important, such as walkways, ligna platformo kaj kovrilo cemento grundo, kaj interetaĝoj.

When comparing steel grating vs plank grating, one of the key differences is their construction. Steel grating is typically heavier and more rigid due to its welded design, while plank grating is lighter and more flexible, allowing for easy installation and customization.

In terms of load-bearing capacity, steel grating is generally stronger and can support heavier loads compared to plank grating. This makes it suitable for heavy industrial environments where heavy equipment and machinery are present.

However, plank grating offers better ventilation and light transmission, making it a preferred choice for applications where air circulation and visibility are important. Its slip-resistant surface also provides added safety for workers in wet or oily conditions.

Another factor to consider when choosing between steel grating and plank grating is maintenance. Steel grating requires minimal maintenance due to its durable and corrosion-resistant nature, making it a cost-effective long-term solution. On the other hand, plank grating may require more frequent cleaning and upkeep to prevent debris buildup and ensure optimal performance.

When it comes to cost, steel grating is generally more expensive upfront due to its higher material and manufacturing costs. However, its long lifespan and low maintenance requirements can result in overall cost savings in the long run. Plank grating, while more affordable initially, may incur higher maintenance and replacement costs over time.

In conclusion, both steel grating and plank grating have their own unique strengths and advantages. The choice between the two depends on the specific requirements of the application, including load-bearing needs, ventilation, maintenance, and cost considerations.

Ultimately, it is important to carefully evaluate the factors and consult with industry experts to determine the most suitable grating solution for your project.