Steel grating and press-locked grating are two popular types of gratings used in various industrial applications. Both have their own unique features and advantages, making it important to understand the differences between them.

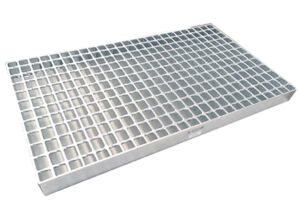

Steel grating is manufactured by forging and welding steel bars into a grid pattern. It is known for its high strength, durability, and load-bearing capacity, making it suitable for heavy-duty applications such as industrial flooring, catwalks, and stair treads. Press-locked grating, on the other hand, is made by permanently locking crossbars and bearing bars together under high pressure, resulting in a smooth and flat surface. It is often used in architectural and commercial applications where aesthetics and slip resistance are important considerations.

One of the key differences between steel grating and press-locked grating lies in their manufacturing process. Steel grating is typically produced through a combination of forging and welding, which results in a rugged and robust structure. Press-locked grating, on the other hand, is manufactured by interlocking crossbars and bearing bars under high pressure, creating a sleek and seamless appearance.

In terms of load-bearing capacity, steel grating is known for its exceptional strength and durability, making it suitable for heavy-duty applications where high load-bearing capacity is essential. Press-locked grating, while still strong and durable, may not be as well-suited for extremely heavy loads as steel grating.

When it comes to installation and maintenance, steel grating is relatively easy to install and requires minimal maintenance, making it a cost-effective choice for many industrial applications. Press-locked grating, with its smooth and flat surface, is easy to clean and maintain, making it ideal for architectural and commercial applications where aesthetics are a priority.

Another important consideration when choosing between steel grating and press-locked grating is the level of slip resistance. 钢格板, with its rugged and serrated surface, offers excellent slip resistance, making it suitable for applications where safety is a concern. Press-locked grating, with its smooth and flat surface, may offer less slip resistance in comparison to steel grating.

In terms of customization, both steel grating and press-locked grating can be customized to meet specific requirements. Steel grating can be customized in terms of bar spacing, surface treatment, and overall design to suit different applications. Press-locked grating can also be customized in terms of bar spacing, crossbar design, and surface finish to achieve the desired aesthetic and functional requirements.

It is important to consider the specific requirements of the application when choosing between steel grating and press-locked grating. For heavy-duty industrial applications where strength and load-bearing capacity are crucial, steel grating may be the preferred choice. For architectural and commercial applications where aesthetics and slip resistance are important considerations, press-locked grating may be the more suitable option.

In conclusion, both steel grating and press-locked grating are versatile and durable options for a wide range of industrial and commercial applications. Understanding the differences between the two types of gratings is essential in selecting the most suitable option for a specific application.