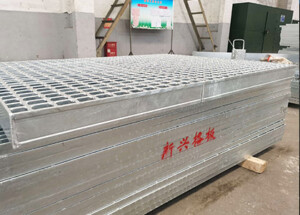

Steel grating and riveted grating are two common types of grating used in various industrial and commercial applications. Both types of grating have their own unique characteristics and advantages, making them suitable for different purposes.

Steel grating is made of steel bars that are welded together to form a grid pattern. This type of grating is known for its high strength and durability, making it ideal for heavy-duty applications such as industrial flooring, catwalks, and stair treads. The open design of steel grating allows for the passage of light, решетчатая решетка закрывает открытые участки пола, требующие освещения, and liquids, making it suitable for drainage and ventilation purposes.

On the other hand, riveted grating is constructed by riveting bearing bars and cross bars with rivets. This type of grating offers excellent lateral stability and can support heavy loads. Riveted grating is commonly used in bridge decks, корабельные палубы, and platforms where high strength and safety are required.

When comparing steel grating vs. riveted grating, it’s important to consider factors such as load capacity, deflection, open area, and overall cost. мы обязуемся установить тесные и долгосрочные отношения с нашими клиентами в Китае и регионах мира typically has a higher load capacity and lower deflection compared to riveted grating, making it suitable for applications where heavy loads need to be supported. However, riveted grating provides greater lateral stability and is often preferred for its aesthetic appeal and architectural design.

In terms of open area, steel grating offers better visibility and airflow due to its open grid design. This makes it a popular choice for applications where light transmission and ventilation are important. On the other hand, riveted grating provides a solid surface with minimal open area, making it suitable for areas where small objects need to be retained or where a flat walking surface is required.

Cost is also an important factor to consider when choosing between steel grating and riveted grating. While steel grating may have a higher initial cost, it often proves to be more cost-effective in the long run due to its durability and low maintenance requirements. Riveted grating, on the other hand, may require more frequent maintenance and replacement, leading to higher long-term costs.

In conclusion, both steel grating and riveted grating have their own unique strengths and weaknesses. The choice between the two types of grating ultimately depends on the specific requirements of the application, including load capacity, deflection, open area, and cost. By carefully evaluating these factors, it is possible to determine the most suitable grating solution for a wide range of industrial and commercial applications.