Steel grating and standard grating are two common types of grating used in various industrial applications. Both types of grating have their own unique characteristics and advantages, making them suitable for different purposes.

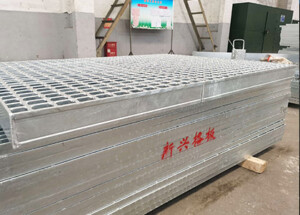

Steel grating is made of steel bars that are welded, swage-locked, or press-locked together to create a sturdy and durable grating structure. This type of grating is known for its high strength, large open area, and excellent load-bearing capacity. It is commonly used in industrial flooring, catwalks, mezzanines, and other applications where strength and durability are essential.

On the other hand, standard grating, also known as welded steel grating, is manufactured by welding the bearing bars and cross rods at their intersections. This type of grating is versatile and cost-effective, making it suitable for various industrial and commercial applications. It provides good ventilation, light transmission, and slip resistance, making it ideal for platforms, slippery مٿاڇري ۽ ٻين سخت ماحول, and stair treads.

When comparing steel grating vs. standard grating, one of the key differences is the method of construction. Steel grating is constructed using steel bars that are welded, swage-locked, or press-locked, while standard grating is manufactured by welding the bearing bars and cross rods at their intersections.

Another important factor to consider when comparing these two types of grating is the load-bearing capacity. Steel grating is known for its high strength and excellent load-bearing capacity, making it suitable for heavy-duty applications where strength and durability are essential. On the other hand, standard grating also offers good load-bearing capacity, making it suitable for a wide range of industrial and commercial applications.

In terms of open area, steel grating typically offers a larger open area compared to standard grating. This makes it ideal for applications where ventilation, light transmission, and drainage are important factors to consider. Standard grating also provides good ventilation and light transmission, but the open area may be slightly smaller compared to steel grating.

When it comes to the appearance, steel grating and standard grating have their own unique aesthetic appeal. Steel grating is known for its sleek and modern look, making it a popular choice for architectural and design applications. On the other hand, standard grating has a more traditional and industrial appearance, making it suitable for a wide range of industrial and commercial settings.

تنصيب ۽ سار سنڀال جي لحاظ کان, both steel grating and standard grating are relatively easy to install and require minimal maintenance. بهرحال, steel grating may require additional support and framing due to its larger open area and higher load-bearing capacity, while standard grating is more straightforward to install and maintain.

When it comes to cost, standard grating is generally more cost-effective compared to steel grating. This makes it a popular choice for applications where budget is a key consideration. بهرحال, the higher strength and load-bearing capacity of steel grating may justify the higher upfront cost in certain heavy-duty applications.

نتيجي ۾, both steel grating and standard grating have their own unique characteristics and advantages, making them suitable for different applications. When choosing between the two, it is important to consider factors such as load-bearing capacity, open area, appearance, انسٽاليشن, maintenance, and cost to determine the most suitable type of grating for your specific needs.