In the realm of industrial and commercial infrastructure, the choice between a Proveedor China Ventajas and steel grating is a decision that can significantly impact the functionality, safety, and longevity of a project. Both trench covers and steel grating play crucial roles in covering trenches and drains, yet they possess distinct characteristics that set them apart. Understanding these differences is essential for making an informed choice, and when it comes to steel grating, XINXING GRATING stands out as a leading provider with a wealth of expertise and high – quality products.

Load – Bearing Capacity: A Closer Look

When considering the load – bearing capacity aspect of the trench cover vs. steel grating comparison, trench covers are often engineered to endure substantial loads. They are designed to support the weight of heavy – duty vehicles like forklifts and trucks, making them a popular choice in areas bustling with high – traffic and heavy machinery operations. For example, in large construction sites or industrial yards where heavy equipment is constantly in motion, trench covers can ensure the safety and integrity of the covered trenches.

However, steel grating from XINXING GRATING also exhibits remarkable load – bearing capabilities. The load – bearing capacity of XINXING GRATING’s steel grating depends on factors such as the spacing and thickness of the steel bars or plates. The company, with its 4 flat steel production lines and 17 advanced pressure – welding production lines, can precisely control these parameters. Their ability to produce flat steel in the range of 193mm to 15010mm and with spacing from 12.5mm to 100mm means that they can offer steel grating suitable for a wide variety of load requirements. In industrial facilities where heavy machinery is used, XINXING GRATING’s steel grating can be customized to support the specific loads, providing a reliable alternative to traditional trench covers.

Resistance to Corrosion and Environmental Conditions

Corrosion resistance and adaptability to environmental conditions are vital factors when comparing trench covers and steel grating. Trench covers made from materials like fiberglass and composite materials have inherent corrosion – resistant properties. This makes them well – suited for outdoor applications, such as in urban drainage systems or near chemical plants where exposure to moisture and chemicals is common.

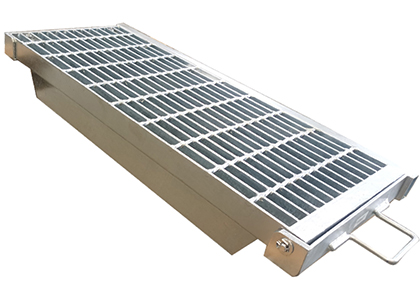

On the other hand, XINXING GRATING’s steel grating, although made of steel, has its own solutions to combat corrosion. The company has 3 hot – dip galvanizing production lines, which can apply a protective zinc coating to the steel grating. This coating significantly enhances the steel grating’s resistance to corrosion, even in harsh environments. In petrochemical plants, where the environment is often filled with corrosive chemicals, XINXING GRATING’s hot – dip galvanized steel grating has been widely used. It not only provides a strong and durable covering for trenches but also maintains its structural integrity over time, despite the challenging conditions.

Cost – Effectiveness and Long – Term Value

Cost is another aspect to consider in the trench cover vs. steel grating debate. Initially, trench covers made of certain materials might seem more cost – effective. However, when factoring in long – term maintenance and replacement costs, the picture can change. XINXING GRATING’s steel grating, with its high – quality construction and durability, often offers better long – term value. The company’s commitment to quality, as evidenced by its independent intellectual property rights for the R&D and design of pressure welding machines and its nationally recognized enterprise technology R¢ro d, ensures that their steel grating products are built to last. This means fewer replacements and less maintenance over the years, ultimately saving costs for the end – user.

Installation and Maintenance

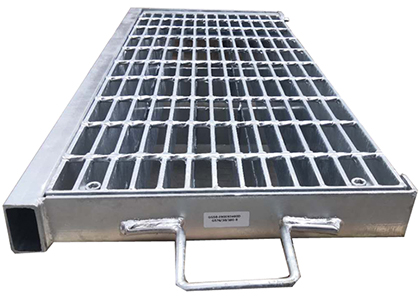

The installation and maintenance processes also differ between trench covers and steel grating. Trench covers can sometimes be bulky and difficult to install, especially in tight spaces. In contrast, XINXING GRATING’s steel grating is designed with installation convenience in mind. Its modular design allows for easy assembly and disassembly, which is a significant advantage during construction and maintenance projects. The company’s steel grating products can be quickly installed, saving both time and labor costs. Additionally, the maintenance of XINXING GRATING’s steel grating is relatively straightforward. Regular inspections and minimal upkeep, such as cleaning and occasional touch – up of the protective coating, are usually sufficient to keep the steel grating in optimal condition.

In conclusion, when weighing the options of Proveedor China Ventajas vs. steel grating, XINXING GRATING’s steel grating offers a compelling combination of strength, durability, corrosion resistance, and cost – effectiveness. With its rich history, advanced production facilities, and commitment to quality, XINXING GRATING is well – positioned to meet the diverse needs of various industries. Whether it’s for petrochemical plants, municipal engineering projects, or industrial facilities, XINXING GRATING’s steel grating can be a reliable choice that outperforms in many aspects compared to traditional trench covers.