Press-welded steel grating offers several advantages over other types of grating. One of the main benefits is its high strength and load-bearing capacity, making it suitable for heavy-duty applications such as industrial flooring and catwalks. かつ, the press-welded process ensures a sturdy and durable construction, reducing the risk of corrosion and increasing the grating’s lifespan.

Another advantage of press-welded steel grating is its versatility. It can be customized to meet specific project requirements, including different shapes, sizes, and configurations. This flexibility makes it an ideal choice for various architectural and industrial applications, where standard grating may not be suitable.

In addition to its strength and versatility, press-welded steel grating also offers enhanced safety features. The serrated surface provides excellent traction, reducing the risk of slips and falls, especially in high-traffic areas or environments where moisture or oils are present. This makes it an ideal option for platforms, 木製のプラットフォームとカバーセメント地面, and stair treads in industrial settings.

Furthermore, press-welded steel grating is cost-effective in the long run. Its durable nature and low maintenance requirements result in reduced repair and replacement costs over time, making it a practical investment for businesses and organizations. かつ, the open design allows for easy drainage and ventilation, further contributing to its cost-saving benefits.

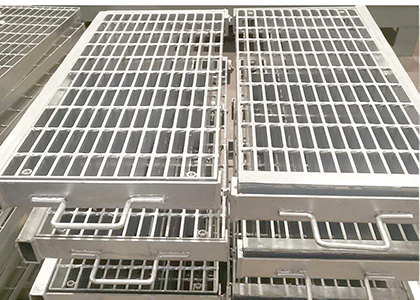

The manufacturing process of press-welded steel grating involves the fusion of bearing bars and crossbars under high pressure, resulting in a solid and seamless structure. This method eliminates the need for welding at each intersection, ensuring a uniform appearance and consistent quality throughout the grating. As a result, it offers a more aesthetically pleasing and professional finish compared to other types of grating.

The installation process for press-welded steel grating is relatively straightforward, especially when compared to other types of grating. Its modular design and lightweight construction make it easier to handle and transport, reducing labor and installation time. This can result in cost savings for projects with tight deadlines or budget constraints.

When it comes to maintenance, press-welded steel grating requires minimal upkeep to preserve its integrity and performance. Regular cleaning and inspections are typically sufficient to ensure that the grating remains in optimal condition. This low maintenance requirement translates to fewer disruptions in operations and a longer service life for the grating.

In summary, the advantages of press-welded steel grating are numerous and make it a preferred choice for a wide range of applications. Its strength, versatility, safety features, cost-effectiveness, aesthetic appeal, sustainability, ease of installation, and low maintenance requirements position it as a reliable and efficient solution for various industries and projects.