When it comes to steel grating, there are two main types to consider: welded steel grating and griglia in acciaio pressata. Both of these options have their own unique characteristics and advantages, making them suitable for different applications.

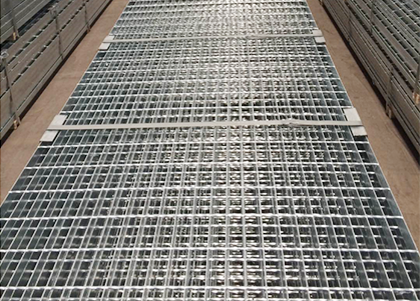

Welded steel grating is manufactured by electronically fusing the cross rods and bearing bars at high pressure and temperature. This process produces a sturdy and durable grating that is resistant to impact and fatigue. Da l'altra parte, press-locked steel grating is constructed by permanently locking the cross bars into the bearing bars by deforming the metal. This results in a grating with a smooth and clean look, making it ideal for architectural applications.

One of the key differences between welded and press-locked steel grating is the method of construction. Welded steel grating is created through the process of resistance welding, which ensures a strong and secure bond between the cross rods and bearing bars. Press-locked steel grating, da l'altra parte, is manufactured by interlocking the cross bars with the bearing bars under high pressure, creating a flush and seamless appearance.

In terms of load capacity, welded steel grating is known for its high strength and load-bearing capabilities, making it suitable for heavy-duty applications such as industrial flooring, ramps, and walkways. Press-locked steel grating, while still strong and durable, may have slightly lower load capacity compared to welded grating, but it offers a more aesthetic appeal and is often used in architectural and decorative applications.

Another important factor to consider when choosing between welded and press-locked steel grating is the ease of customization. Welded steel grating can be easily customized to meet specific size and shape requirements, making it a versatile option for various projects. Press-locked steel grating, da l'altra parte, may have limitations when it comes to customization due to its interlocking design, which may require additional engineering and manufacturing processes.

Quandu si tratta di installazione, both welded and press-locked steel grating offer easy and straightforward installation processes. Eppuru, welded steel grating may require welding on site, which can add to the installation time and cost. Press-locked steel grating, da l'altra parte, can be installed quickly and efficiently without the need for welding, making it a cost-effective option for many projects.

In termini di mantenimentu, both welded and press-locked steel grating are relatively low-maintenance options. Eppuru, welded steel grating may require more frequent maintenance due to the welding joints, which can be prone to corrosion and wear over time. Press-locked steel grating, with its seamless design, may require less maintenance and upkeep, making it a durable and long-lasting choice for many applications.

Quandu si tratta di costu, welded steel grating is generally more affordable compared to press-locked steel grating, making it a cost-effective option for projects with budget constraints. Press-locked steel grating, while slightly more expensive, offers a more refined and elegant appearance, making it a popular choice for architectural and decorative applications where aesthetics are a priority.

In riassuntu, the choice between welded and griglia in acciaio pressata ultimately depends on the specific requirements of the project, including load capacity, customization, installation, Mantenimentu, and budget. Both options offer unique benefits and can be tailored to suit a wide range of applications, making them versatile and practical solutions for various industries.