Industrial wastewater management is a critical aspect of environmental protection and sustainability. In this context, trench covers for industrial wastewater channels play a vital role in ensuring safety and efficiency. These covers not only prevent contaminants from escaping but also protect workers and the surrounding environment from potential hazards.

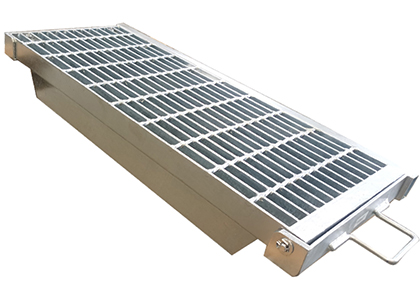

Trench covers for industrial wastewater channels are designed to withstand harsh conditions. They are constructed from durable materials such as steel, fiberglass, or reinforced concrete. These materials ensure longevity and resistance to corrosion, making them suitable for various industrial applications.

One of the primary functions of trench covers is to provide safety for personnel working in industrial settings. By covering open channels, these covers minimize the risk of accidents and injuries. Furthermore, they help maintain a clean and organized work environment, which is essential for operational efficiency.

In addition to safety, trench covers help in maintaining regulatory compliance. Many industries are subject to strict environmental regulations that mandate the proper management of wastewater. Using trench covers ensures that companies adhere to these regulations, thereby avoiding potential fines and legal issues.

The installation of trench covers requires careful planning and execution. It involves assessing the specific needs of the wastewater channels, including load-bearing requirements and environmental factors. Proper installation not only enhances safety but also extends the lifespan of the covers.

Regular maintenance of trench covers is essential to ensure their effectiveness. This includes routine inspections for signs of wear and tear, as well as cleaning to prevent debris accumulation. A well-maintained trench cover will provide reliable protection for years to come.

The design of trench covers can vary significantly based on the application. For instance, covers used in heavy industrial settings may require additional reinforcements to support heavy machinery. Conversely, lighter designs may suffice for less demanding environments.

Another important consideration is the accessibility of trench covers. Many designs incorporate features that allow for easy removal and replacement. This is particularly important when maintenance or inspections of the channels are necessary.

Innovations in trench cover design are continually emerging. Advanced materials and technologies are being developed to enhance durability and functionality. For example, some covers now include integrated drainage systems to further manage wastewater effectively.

Environmental sustainability is a growing concern in industrial operations. Trench covers that are made from recycled or eco-friendly materials can help companies reduce their carbon footprint. This aligns with global efforts to promote sustainable industrial practices.

The cost of trench covers for industrial wastewater channels can vary widely. Factors influencing cost include material choice, size, and custom design requirements. While upfront costs may be significant, the long-term benefits often justify the investment.

Selecting the right trench cover involves understanding the specific requirements of the wastewater system. Factors such as chemical exposure, temperature fluctuations, and load capacity must be considered to ensure optimal performance.

In many cases, trench covers are also designed to provide additional features, such as anti-slip surfaces. This is crucial in preventing slips and falls in environments where water and other substances may create hazards.

Collaboration with experienced suppliers and manufacturers can significantly enhance the selection process. These professionals can provide valuable insights into the best materials and designs for specific applications, ensuring that the trench covers meet all necessary standards.

Training for personnel on the proper handling and maintenance of trench covers is equally important. Ensuring that workers understand the significance of these covers and how to care for them can lead to improved safety and efficiency.

As industries evolve, so do the challenges associated with wastewater management. Trench covers must adapt to meet new demands, such as increased wastewater volumes or stricter regulations. Staying informed about industry trends is essential for effective management.

The role of trench covers extends beyond mere functionality; they also contribute to the overall aesthetic of industrial facilities. A well-designed cover can enhance the appearance of a site while still serving its primary purpose.

In summary, trench covers for industrial wastewater channels are indispensable components of a safe and compliant industrial environment. Their benefits extend to safety, regulatory compliance, and environmental sustainability, making them a worthy investment for any industrial operation.

To conclude, the importance of trench covers cannot be overstated. They play a critical role in protecting both workers and the environment, ensuring that industrial operations can proceed safely and efficiently.

As industries continue to grow and evolve, the demand for effective wastewater management solutions, including trench covers, will remain high. Companies that prioritize these solutions will not only comply with regulations but also enhance their operational efficiency.

The future of trench covers looks promising, with ongoing advancements in materials and design. As technology continues to improve, we can expect even more innovative solutions that address the challenges of industrial wastewater management.