Trench covers for railway tracks are essential components in the infrastructure of rail systems. They serve multiple purposes, including protecting the underlying utilities and ensuring the safety of both passengers and maintenance personnel. The design and material selection for these trench covers are critical factors that influence their performance and longevity.

One of the primary functions of trench covers for railway tracks is to provide a safe walking surface for workers who need to access the tracks for maintenance or inspections. These covers must be sturdy enough to withstand heavy loads from trains and equipment, while also being light enough for easy handling and installation. The right balance of strength and weight is crucial in their design.

In addition to safety, trench covers for railway tracks also play a vital role in preventing debris and water from entering the trench. This is particularly important in areas where the tracks are exposed to the elements, as moisture can lead to corrosion of electrical systems and other utilities housed within the trench. Effective drainage solutions are often incorporated into the design of these covers to mitigate such risks.

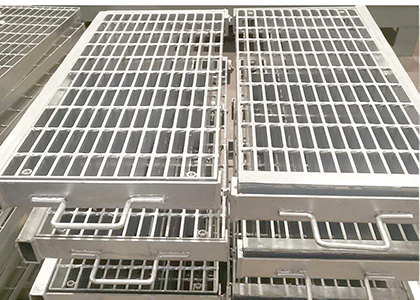

Material choice is a significant aspect of manufacturing trench covers for railway tracks. Common materials include steel, aluminum, and composite materials, each offering different benefits and drawbacks. Steel covers are known for their durability but can be heavy, while aluminum offers a lighter alternative with good corrosion resistance. Composite materials often combine the best features of both, providing strength and reduced weight.

The installation process of trench covers for railway tracks requires careful planning and execution. It is essential to ensure that the covers fit snugly into the trench without any gaps that could pose safety hazards. Proper alignment and securing methods are necessary to maintain the integrity of the cover and prevent displacement during train operations.

Regular maintenance of trench covers for railway tracks is crucial to ensure their continued effectiveness. Inspections should be conducted routinely to check for signs of wear, damage, or misalignment. Any issues should be addressed promptly to prevent accidents and maintain the safety of the rail system.

In terms of environmental considerations, trench covers for railway tracks can also be designed to be more sustainable. Using recycled materials or designing for ease of recycling at the end of their life cycle can significantly reduce the environmental impact. Additionally, covers can be designed to allow for vegetation growth, which can help manage stormwater runoff and improve biodiversity.

The cost of trench covers for railway tracks can vary widely based on materials, design complexity, and manufacturing processes. While it may be tempting to opt for the cheapest option, investing in high-quality covers can lead to long-term savings by reducing maintenance needs and enhancing safety.

Innovative designs in trench covers for railway tracks are continually being developed to improve performance. For example, some manufacturers are now producing covers with integrated sensors that can monitor the condition of the track and the trench itself. This technology can provide real-time data to maintenance teams, allowing for proactive measures to be taken before issues arise.

The regulatory environment surrounding trench covers for railway tracks is also an important consideration. Compliance with safety standards and regulations is mandatory, and manufacturers must stay updated on any changes to these requirements. This ensures that the covers not only meet the necessary safety criteria but also promote best practices within the industry.

Training for personnel involved in the installation and maintenance of trench covers for railway tracks is essential. Proper training ensures that workers understand the importance of these covers and the correct procedures for handling and maintaining them. This can significantly reduce the risk of accidents and injuries on the job.

The future of trench covers for railway tracks looks promising, with advancements in materials science and engineering paving the way for even more durable and efficient designs. Innovations such as lightweight composites and smart materials that respond to environmental conditions are on the horizon, potentially revolutionizing how these covers are used.

Collaboration between manufacturers, rail operators, and regulatory bodies is vital in driving improvements in trench cover design and application. By working together, stakeholders can share insights and best practices that enhance safety and efficiency across rail networks.

In summary, trench covers for railway tracks are a critical component of railway infrastructure, ensuring safety and functionality. Their design, material selection, and maintenance practices are essential to the overall performance of rail systems. As technology advances, we can expect to see even more innovative solutions that will enhance the safety and efficiency of these vital components.

The role of trench covers in urban rail systems cannot be overstated. In densely populated areas, the presence of utilities beneath the tracks is common, making trench covers essential for safe access and maintenance. Their design must consider not only the structural requirements but also the urban environment they are situated in.

Furthermore, trench covers for railway tracks can contribute to the aesthetic appeal of rail corridors. Some designs incorporate artistic elements or green features that blend with the surrounding landscape, enhancing the visual experience for passengers and pedestrians alike. This aspect of design is increasingly being recognized as important in modern urban planning.

The impact of trench covers on operational efficiency is another area worth exploring. Effective trench covers can reduce downtime during maintenance operations, allowing for quicker access and repairs. This, in turn, minimizes disruptions to train schedules and improves overall service reliability for passengers.

In conclusion, trench covers for railway tracks are more than just functional components; they are integral to the safety, efficiency, and sustainability of railway operations. As the industry evolves, ongoing innovation and collaboration will be key to meeting the challenges of modern rail systems.